Y Strainers vs. Basket Strainers: A Comparative Analysis

Strainers are vital components in a wide range of industrial and household setups, essential for effectively filtering liquids. Among the various types available, Y strainers and basket strainers are notably popular. Despite both aiming for liquid filtration, they differ significantly in their design, how they work, and where they're used. This article aims to compare and analyze these two types of strainers.

1. Structural Overview

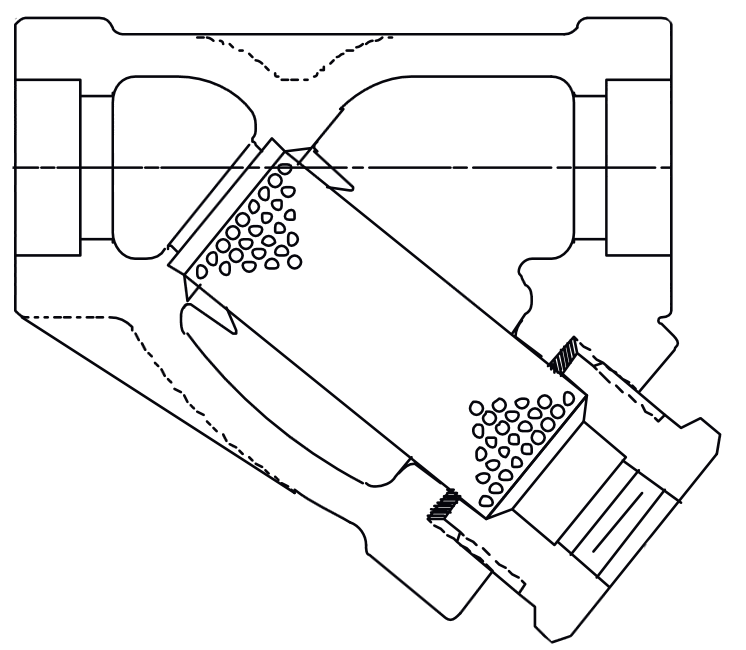

Y Strainers:

Y strainers consist of key parts like a valve body, valve cover, valve seat, valve disc, and strainer. The valve body takes on a Y shape, featuring two ports—a designated inlet and outlet. These ports connect via the valve seat and valve disc, creating a sealed pathway. The strainer, crucial for filtration, sits within the valve seat.

Y strainers consist of key parts like a valve body, valve cover, valve seat, valve disc, and strainer. The valve body takes on a Y shape, featuring two ports—a designated inlet and outlet. These ports connect via the valve seat and valve disc, creating a sealed pathway. The strainer, crucial for filtration, sits within the valve seat.

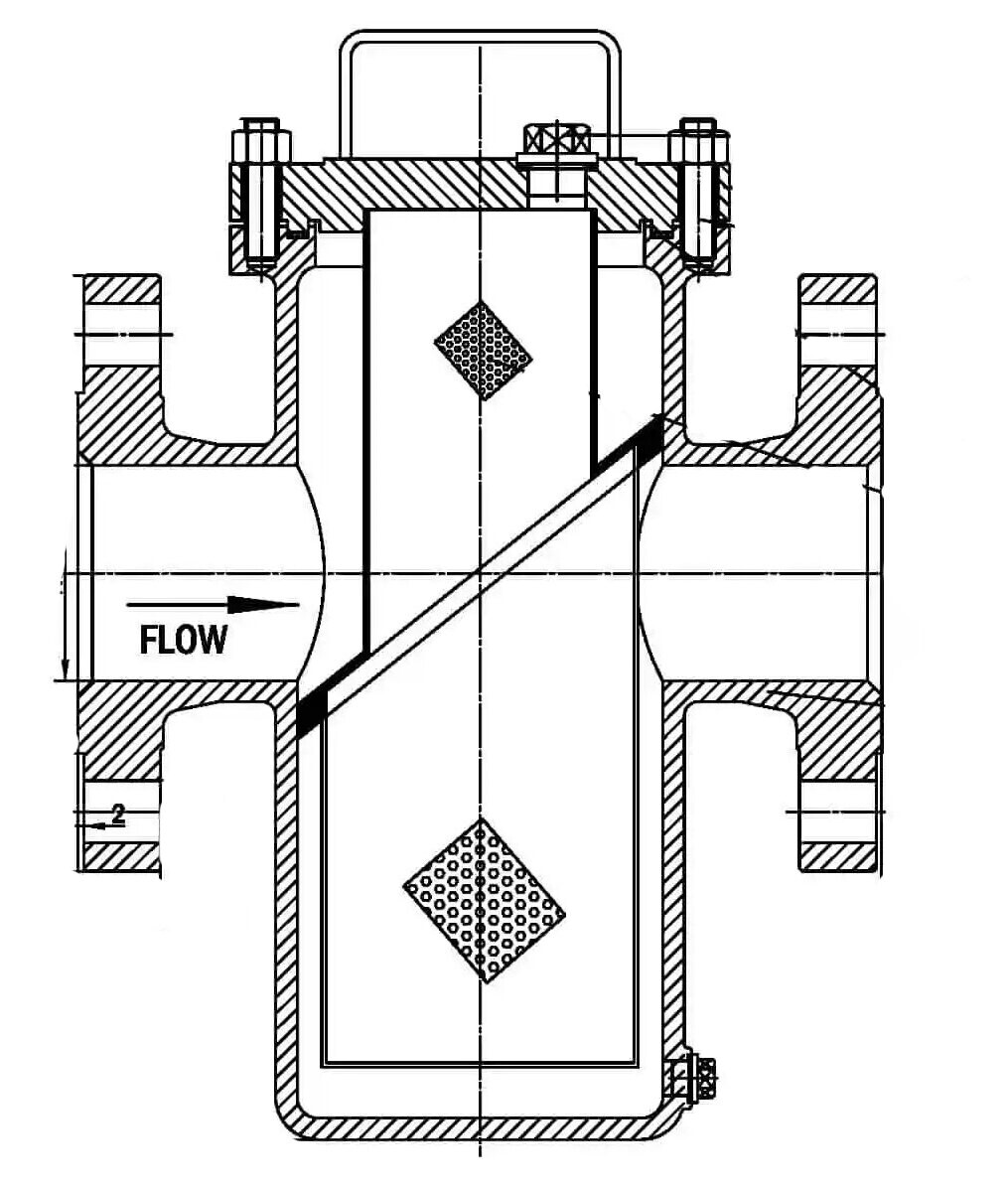

Basket Strainers:

Basket strainers come with a housing, strainer element, flanges, and additional components. The housing houses a basket designed to hold the strainer element, which is easily removable and replaceable. Liquid enters from one side of the housing, passes through the strainer element, and exits from the opposite side.

2. Operational Principles

Y Strainers:

Y strainers operate by regulating fluid flow and filtration through the movement of the valve disc between the inlet and outlet. As liquid enters through the inlet, the valve disc opens, allowing the liquid to pass through the strainer before exiting via the outlet. Closing the valve disc stops liquid flow when necessary.

Basket Strainers:

Basket strainers rely on the strainer element to capture impurities in the liquid. Liquid enters, travels through the strainer element within the basket, and gets rid of contaminants. Regularly replacing the strainer element is vital for maintaining optimal filtration effectiveness.

Y strainers operate by regulating fluid flow and filtration through the movement of the valve disc between the inlet and outlet. As liquid enters through the inlet, the valve disc opens, allowing the liquid to pass through the strainer before exiting via the outlet. Closing the valve disc stops liquid flow when necessary.

Basket Strainers:

Basket strainers rely on the strainer element to capture impurities in the liquid. Liquid enters, travels through the strainer element within the basket, and gets rid of contaminants. Regularly replacing the strainer element is vital for maintaining optimal filtration effectiveness.

3. Application Scenarios

Y Strainers:

Y strainers are widely used in pipeline systems for fluid filtration and flow control. They prevent impurities from reaching equipment through pipelines, safeguarding equipment integrity. Moreover, they facilitate fluid flow control, simplifying pipeline maintenance and repairs.

Basket Strainers:

Basket strainers play crucial roles in both initial and final liquid treatment processes. They excel in filtering suspended solids, particles, microorganisms, and other impurities, ensuring liquid cleanliness. Consequently, they're widely utilized across industries such as chemicals, petroleum, pharmaceuticals, and food production.

Y strainers are widely used in pipeline systems for fluid filtration and flow control. They prevent impurities from reaching equipment through pipelines, safeguarding equipment integrity. Moreover, they facilitate fluid flow control, simplifying pipeline maintenance and repairs.

Basket Strainers:

Basket strainers play crucial roles in both initial and final liquid treatment processes. They excel in filtering suspended solids, particles, microorganisms, and other impurities, ensuring liquid cleanliness. Consequently, they're widely utilized across industries such as chemicals, petroleum, pharmaceuticals, and food production.

In summary, while Y strainers and basket strainers share the common goal of liquid filtration, their differences in design, operation, and applications are significant. To select the right strainer and achieve efficient filtration, a thorough assessment of specific operational requirements and environmental factors is essential.