Lift Plug Valve: Structure, Types and Applications

The lift plug valve stands out as a crucial component in fluid control systems across industries, appreciated for its exceptional performance and distinctive design. This article provides an in-depth exploration of the structure, operational principles, and diverse application domains of the lift plug valve.

1. Structure and Working Principles

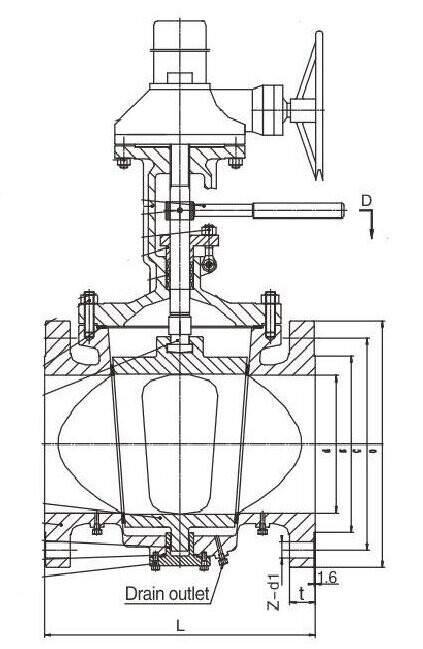

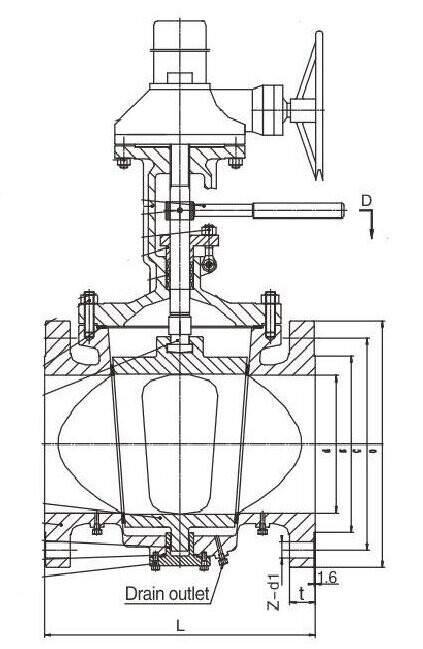

The basic structure of the lift plug valve includes the plug body, valve seat, actuator, and other components. The plug body is raised or lowered by the actuator to control the flow of fluid. The working principles are as follows:

2. Types and Features

The lift plug valve can be classified into two main types based on sealing methods and operating principles: soft-seated and metal-seated.

3. Application Areas

The lift plug valve finds extensive applications across various industries, including but not limited to:

As an excellent fluid control solution, the lift plug valve is favored in industrial applications for its reliable sealing performance, flexible operation, and wide range of applications. Different types of lift plug valves cater to diverse fluid control needs, providing solutions for various industrial scenarios. In the future of industrial development, the lift plug valve will continue to play a crucial role, supporting industrial production and urban construction with its reliability and versatility.

1. Structure and Working Principles

The basic structure of the lift plug valve includes the plug body, valve seat, actuator, and other components. The plug body is raised or lowered by the actuator to control the flow of fluid. The working principles are as follows:

- Opening Process: The actuator rotates or lifts the plug body, separating it from the valve seat and rotating it to the open position. During this process, fluid flows freely through the valve, ensuring unimpeded pipeline flow.

- Closing Process: The actuator rotates the plug body to the closed position, causing it to tightly seal against the valve seat, preventing fluid flow through the valve. This closed state ensures the safety and integrity of the pipeline system.

2. Types and Features

The lift plug valve can be classified into two main types based on sealing methods and operating principles: soft-seated and metal-seated.

- Twin Seal Lift Plug Valve: This type employs a flexible sealing structure, typically composed of rubber sealing surfaces. During the opening process, the plug body separates from the valve seat and rotates, causing the sealing surfaces to separate. During the closing process, the plug body tightly contacts the valve seat, forming a secure seal.

- Metal-Seated Lift Plug Valve: With metal sealing surfaces, this type offers high wear resistance and temperature resistance. Controlled by a handwheel or mechanical drive device, the plug body moves up and down, enabling valve opening and closing. Its stable sealing performance makes it suitable for harsh environments with high temperatures and pressures.

3. Application Areas

The lift plug valve finds extensive applications across various industries, including but not limited to:

- Chemical Industry: Used for controlling the flow of chemical media such as acids, alkalis, and solvents.

- Oil and Gas Industry: Employed in pipeline systems for fluid control, ensuring safe and stable pipeline operations.

- Power Generation Industry: Utilized in circulating water systems of thermal power plants to regulate water flow.

- Pharmaceutical and Food Industry: Applied in production processes for fluid control, ensuring clean and safe production environments.

- Municipal Engineering: Installed in water supply and drainage systems to maintain the functionality of urban infrastructure.

As an excellent fluid control solution, the lift plug valve is favored in industrial applications for its reliable sealing performance, flexible operation, and wide range of applications. Different types of lift plug valves cater to diverse fluid control needs, providing solutions for various industrial scenarios. In the future of industrial development, the lift plug valve will continue to play a crucial role, supporting industrial production and urban construction with its reliability and versatility.