What You Should Know about Orbit Ball Valves?

On this page

Orbit ball valves stand out as a dependable choice for contemporary pipeline systems, alongside gate valves, playing a pivotal role in fluid flow regulation, distribution, and redirection. This type of ball valve has garnered widespread adoption across industries such as petroleum, natural gas, chemicals, and environmental protection, owing to its reliability and versatility.

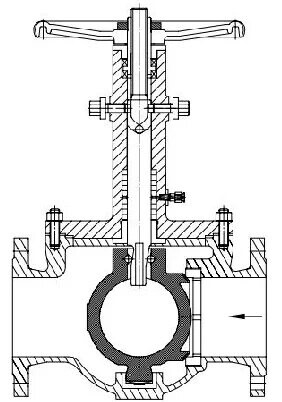

The operating principles of orbit ball valves are based on a unique design that allows for improved sealing performance and reduced wear compared to traditional ball valves. Here's a detail introduction of the operating principles of orbit ball valves: Initially, the ball is pressed against the valve seat by the valve stem in the closed position.

A counterclockwise rotation of the handwheel prompts the valve stem to move, allowing the ball to disengage from the seat.

As the valve stem ascends, it engages with a guide pin within its spiral groove, enabling smooth rotation of the ball.

Upon reaching maximum height, the valve stem rotates the ball to the fully open position. Clockwise rotation of the handwheel initiates the descent of the valve stem, causing the ball to disengage and rotate.

Further rotation of the handwheel results in simultaneous rotation of the valve stem and ball, completing a 90° rotation.

As closure nears, the ball rotates 90° without contacting the seat.

During the final rotations, the angled plane at the valve stem's bottom wedges the ball tightly against the seat, ensuring complete sealing.

Orbit ball valves offer advanced features that ensure reliable fluid control in modern pipeline systems.

- Frictionless Operation: The frictionless design mitigates sealing issues caused by traditional valve surfaces, enhancing the lifespan of sealing components.

- Top-Entry Design: Facilitates easy replacement and maintenance of internal valve components, reducing downtime and associated costs.

- Single-Seat Design: Eliminates safety concerns related to abnormal pressure buildup within the valve cavity.

- Low Torque Design: Swift, low-torque operation simplifies opening and closing.

- Wedge Sealing Structure: Achieves sealing by mechanically pressing the ball against the seat, ensuring consistent performance under varying pressure conditions.

- Self-Cleaning Seal Surface: Uniform fluid flow along the ball's sealing surface eliminates scouring and flushes away deposits, enhancing sealing lifespan.

Orbit ball valves find utility in diverse pipeline and station setups, including those involved in the transportation of petroleum, natural gas, chemical processing, airport operations, and environmental protection endeavors. They are particularly valued for their ability to swiftly halt fluid flow when necessary.

In conclusion, the advantages of orbit ball valves in modern pipeline systems are evident in their unique design, enhanced sealing performance, and versatile features. With frictionless operation, a top-entry design for easy maintenance, and applications across diverse industries, orbit ball valves offer a reliable solution for fluid control, making them a valuable choice in contemporary pipeline systems.