Mitigating Risks: Abnormal Pressure Rise in Gate Valves

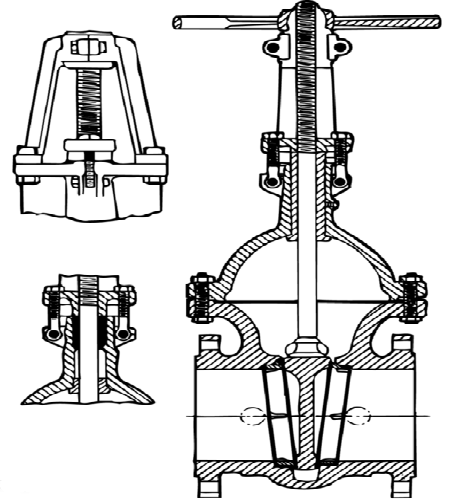

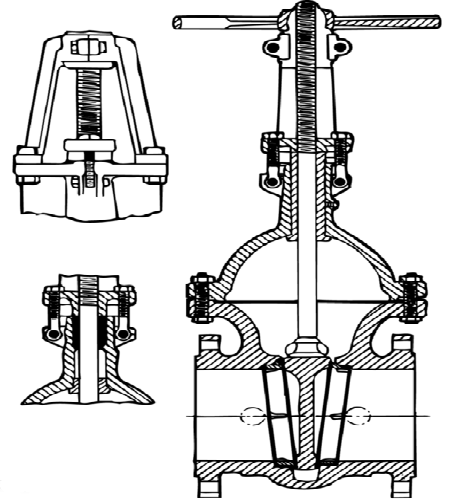

Gate valves serve as vital components in industrial process control, regulating the flow of fluids with precision. Despite their importance, abnormal pressure rise can introduce significant risks. This article aims to delve into the perils associated with abnormal pressure rise in gate valves and propose comprehensive protective measures.

Hazards of Abnormal Pressure Rise in Gate Valves

Gate valves, while fundamental to industrial operations, are not immune to the threats posed by abnormal pressure surges. Understanding these risks is paramount to safeguarding the integrity of industrial processes. Below are key hazards associated with abnormal pressure rise in gate valves:

Protective Measures for Gate Valve Overpressure

Gate valve overpressure presents formidable challenges to industrial operations, including structural integrity risks, fluid leakage, and compromised process control. Employing robust protective measures is indispensable to mitigate these risks and ensure the continuous and secure operation of gate valves. Here are key protective measures:

In conclusion, Proactive consideration of abnormal pressure rise is crucial in gate valve design and installation. Heightened vigilance, particularly for high-temperature, high-pressure, and large-diameter valves, is essential for equipment and system safety. By understanding associated hazards and implementing protective measures, accidents can be minimized, ensuring smooth industrial operations.

Hazards of Abnormal Pressure Rise in Gate Valves

Gate valves, while fundamental to industrial operations, are not immune to the threats posed by abnormal pressure surges. Understanding these risks is paramount to safeguarding the integrity of industrial processes. Below are key hazards associated with abnormal pressure rise in gate valves:

1. Structural Damage

Abnormal pressure surges exert undue stress on gate valve components, surpassing their design limitations. This stress can culminate in structural damage such as fractures, compromising the valve's functionality and potentially leading to catastrophic failure of the assembly.

2. System Safety Compromises

Excessive pressure within gate valves may result in the rupture of pressure-bearing components, leading to media leakage. This scenario is particularly perilous when handling high-temperature, toxic, or hazardous gases, posing threats to equipment integrity and personnel safety.

3. Disruptions in Production Control

Uninterrupted valve operation is pivotal for maintaining control over industrial processes. Abnormal pressure surges can necessitate system shutdowns for maintenance, resulting in substantial direct and indirect production losses.

2. System Safety Compromises

Excessive pressure within gate valves may result in the rupture of pressure-bearing components, leading to media leakage. This scenario is particularly perilous when handling high-temperature, toxic, or hazardous gases, posing threats to equipment integrity and personnel safety.

3. Disruptions in Production Control

Uninterrupted valve operation is pivotal for maintaining control over industrial processes. Abnormal pressure surges can necessitate system shutdowns for maintenance, resulting in substantial direct and indirect production losses.

Protective Measures for Gate Valve Overpressure

Gate valve overpressure presents formidable challenges to industrial operations, including structural integrity risks, fluid leakage, and compromised process control. Employing robust protective measures is indispensable to mitigate these risks and ensure the continuous and secure operation of gate valves. Here are key protective measures:

1. Installation of Pressure Relief Ports

Incorporating internally opening pressure relief ports within gate valves facilitates the equilibrium of pressure within the valve cavity. These ports automatically release excess pressure, thereby maintaining balance with upstream pressure and averting abnormal pressure rise.

2. Implementation of External Bypass Pressure Relief

For existing valve systems, the installation of external bypasses and pressure relief valves can effectively alleviate cavity pressure. Controlled manipulation of bypass valves post-main gate closure ensures safe valve operation during shutdown.

3. Deployment of Dedicated Pressure Relief Valves

External pressure relief valves offer precise control over pressure levels within gate valve cavities. They autonomously release pressure during overpressure events, preserving operational safety. Setting pressure thresholds for relief valves should align with the nominal pressure rating of the valve system.

Incorporating internally opening pressure relief ports within gate valves facilitates the equilibrium of pressure within the valve cavity. These ports automatically release excess pressure, thereby maintaining balance with upstream pressure and averting abnormal pressure rise.

2. Implementation of External Bypass Pressure Relief

For existing valve systems, the installation of external bypasses and pressure relief valves can effectively alleviate cavity pressure. Controlled manipulation of bypass valves post-main gate closure ensures safe valve operation during shutdown.

3. Deployment of Dedicated Pressure Relief Valves

External pressure relief valves offer precise control over pressure levels within gate valve cavities. They autonomously release pressure during overpressure events, preserving operational safety. Setting pressure thresholds for relief valves should align with the nominal pressure rating of the valve system.

In conclusion, Proactive consideration of abnormal pressure rise is crucial in gate valve design and installation. Heightened vigilance, particularly for high-temperature, high-pressure, and large-diameter valves, is essential for equipment and system safety. By understanding associated hazards and implementing protective measures, accidents can be minimized, ensuring smooth industrial operations.