Through Conduit Knife Gate Valve: Design, Operation and Applications

The through conduit knife gate valve is a critical component in fluid control systems across various industries. Its unique design and operational principles make it highly effective in regulating fluid flow under diverse conditions. This article explores the structure, operational principles, advantages, and characteristics of the through conduit knife gate valve in industrial applications.

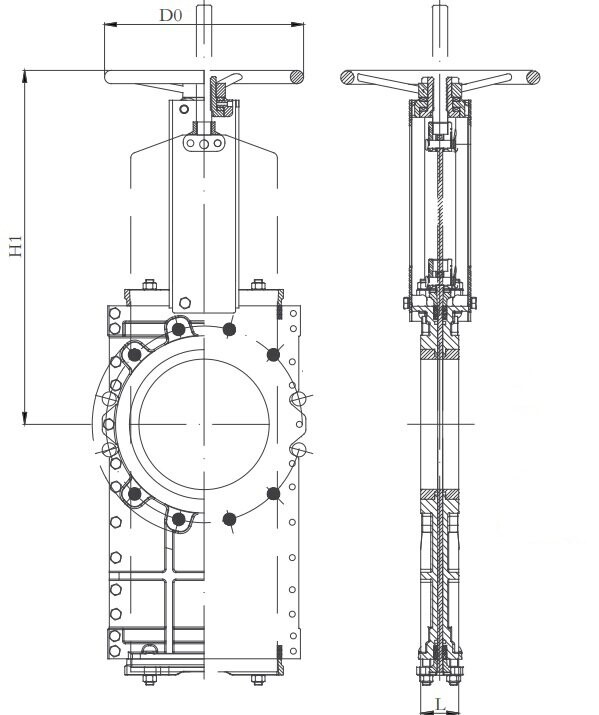

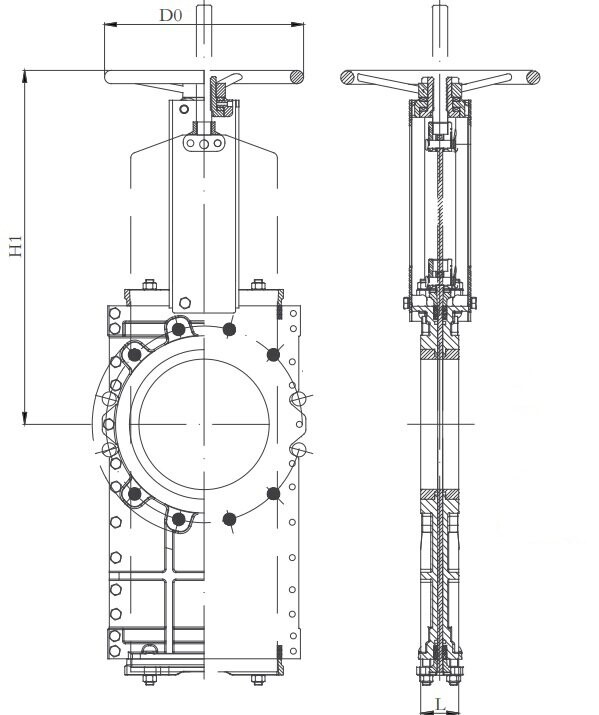

1. Structural Design and Sealing Mechanism

The through conduit knife gate valve relies on a simple yet effective structure for optimal fluid control.

2. Operational Principles

In operation, the gate blade of the through conduit knife gate valve offers swift and precise control over fluid flow.

3. Features and Advantages

Key features of the through conduit knife gate valve include:

4. Application Fields

Through conduit knife gate valves find extensive utility in industries such as petroleum, chemical, power generation, and metallurgy. Their reliable sealing performance and flexible operation make them indispensable in pipeline systems. Particularly in harsh environments involving high pressure, high temperature, or corrosive media, through conduit knife gate valves demonstrate their unique advantages, ensuring reliable industrial production.

With its dependable sealing, flexible operation, and extended lifespan, the through conduit knife gate valve has emerged as a favored choice in fluid control applications. As industrial technologies continue to advance, the through conduit knife gate valve is expected to witness broader adoption and further development in the future.

1. Structural Design and Sealing Mechanism

The through conduit knife gate valve relies on a simple yet effective structure for optimal fluid control.

- Gate Blade and Seat: The valve's core components, the gate blade and seat, form a tight seal through continuous contact. The gate blade features a circular aperture for precise fluid control.

- Groove-Free Design: Unlike other valves, the absence of grooves in the valve body minimizes obstruction, ideal for conveying granular media in powder equipment pipelines.

- Adaptable Sealing: The sealing mechanism can be tailored to incorporate either soft or hard sealing, offering damage resistance and extended longevity.

2. Operational Principles

In operation, the gate blade of the through conduit knife gate valve offers swift and precise control over fluid flow.

Closing Sequence: When closing, the gate blade fully inserts into the valve body, effectively cutting off the connection between upstream and downstream flow paths.

Opening Procedure: Upon opening, the gate blade quickly retracts from the flow channel, restoring fluid passage with efficiency.

Opening Procedure: Upon opening, the gate blade quickly retracts from the flow channel, restoring fluid passage with efficiency.

3. Features and Advantages

Key features of the through conduit knife gate valve include:

- Integral design for reduced fluid resistance and enhanced operational flexibility.

- Dual-plane bearing design for the transmission screw drive, minimizing friction and ensuring smooth valve opening.

- Moveable sealing seat with pre-tensioned O-rings to reduce leakage and automatically compensate for wear over prolonged use.

- Fixed guide claws without grooves, minimizing media buildup or blockages.

- Wide adaptability to various media and operating conditions through the choice of metal-hard or soft sealing options.

- Versatile operation modes including manual, pneumatic, and electric, catering to a wide range of practical applications.

4. Application Fields

Through conduit knife gate valves find extensive utility in industries such as petroleum, chemical, power generation, and metallurgy. Their reliable sealing performance and flexible operation make them indispensable in pipeline systems. Particularly in harsh environments involving high pressure, high temperature, or corrosive media, through conduit knife gate valves demonstrate their unique advantages, ensuring reliable industrial production.

With its dependable sealing, flexible operation, and extended lifespan, the through conduit knife gate valve has emerged as a favored choice in fluid control applications. As industrial technologies continue to advance, the through conduit knife gate valve is expected to witness broader adoption and further development in the future.