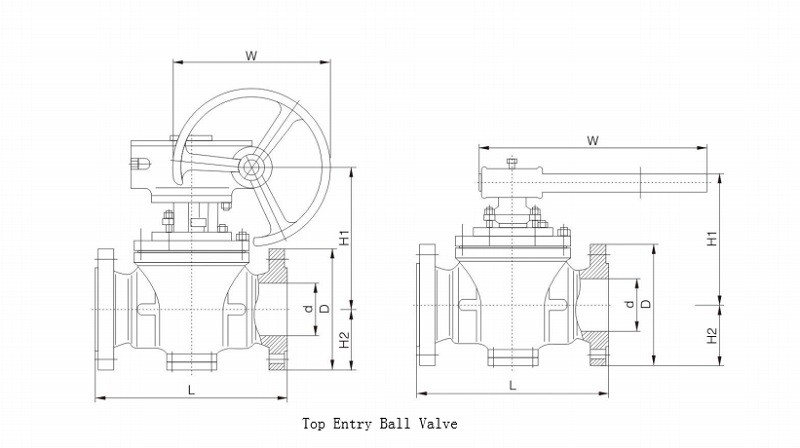

Top Entry Ball Valves for Enhancing Severe Service

Among various industrial valve solutions, top entry ball valve is emerging as game-changers, especially in severe service applications where demands are high, and reliability is paramount. These top entry ball valves, renowned for their compact unibody design and engineered seating technology, are redefining expectations in terms of inline reparability, fugitive emissions compliance, and ease of maintenance.

The Top Entry Design Advantage

Top entry ball valves distinguish themselves in severe service applications by minimizing potential leakage points, addressing concerns related to fugitive emissions and hazardous gases. Their unibody design and inline reparability set them apart from traditional designs, providing solutions for critical applications in challenging environments such as ammonia, hydrofluoric acid, chlorine, ethylene oxide, phosgene, and oxygen.

Unrivaled Maintenance Efficiency

The top entry ball valve's unibody structure, coupled with the ability to maintain the valve inline without removal, ensures quick access to critical components, facilitating efficient maintenance practices. The incorporation of interchangeable modular bonnet designs enhances flexibility and customization to meet specific operating parameters, providing users with versatile solutions.

Engineered Seating Technology

Central to the success of top entry ball valves is their engineered seating technology. Departing from conventional designs, these valves utilize a wedge seat design, similar to a plug valve, ensuring a reliable seal independent of line pressure. This innovative approach, combined with an alternative ball/seat design, extends seat life, minimizes operating torque, and surpasses industry seat shut-off standards, ensuring unmatched reliability even at low pressures.

Looking Ahead

While various valve designs offer distinct advantages, top entry ball valves have been meticulously crafted to meet the specific demands of severe service applications. Their seamless inline maintenance, reliable tight shut-off, and compliance with fugitive emissions standards position them as the preferred choice for critical applications, allowing users to prioritize operational efficiency without compromising on reliability.

The ascendancy of top entry ball valves represents a significant milestone in industrial valve technology, establishing a new standard for efficiency and reliability in severe service applications. With their innovative design and performance capabilities, these valves are poised to play a pivotal role in enhancing operational excellence and meeting the stringent requirements of challenging industrial environments.

The Top Entry Design Advantage

Top entry ball valves distinguish themselves in severe service applications by minimizing potential leakage points, addressing concerns related to fugitive emissions and hazardous gases. Their unibody design and inline reparability set them apart from traditional designs, providing solutions for critical applications in challenging environments such as ammonia, hydrofluoric acid, chlorine, ethylene oxide, phosgene, and oxygen.

Unrivaled Maintenance Efficiency

The top entry ball valve's unibody structure, coupled with the ability to maintain the valve inline without removal, ensures quick access to critical components, facilitating efficient maintenance practices. The incorporation of interchangeable modular bonnet designs enhances flexibility and customization to meet specific operating parameters, providing users with versatile solutions.

Engineered Seating Technology

Central to the success of top entry ball valves is their engineered seating technology. Departing from conventional designs, these valves utilize a wedge seat design, similar to a plug valve, ensuring a reliable seal independent of line pressure. This innovative approach, combined with an alternative ball/seat design, extends seat life, minimizes operating torque, and surpasses industry seat shut-off standards, ensuring unmatched reliability even at low pressures.

Looking Ahead

While various valve designs offer distinct advantages, top entry ball valves have been meticulously crafted to meet the specific demands of severe service applications. Their seamless inline maintenance, reliable tight shut-off, and compliance with fugitive emissions standards position them as the preferred choice for critical applications, allowing users to prioritize operational efficiency without compromising on reliability.

The ascendancy of top entry ball valves represents a significant milestone in industrial valve technology, establishing a new standard for efficiency and reliability in severe service applications. With their innovative design and performance capabilities, these valves are poised to play a pivotal role in enhancing operational excellence and meeting the stringent requirements of challenging industrial environments.