API 6A Wellhead Equipment: Setting the Standard for Oil and Gas Production

In the oil and gas production, API 6A Wellhead Equipment emerges as a beacon of reliability and efficiency. Developed by the American Petroleum Institute (API), API 6A sets the industry standard for wellhead and Christmas tree equipment, so API 6A Wellhead Equipment plays a crucial role in optimizing operations and ensuring safety.

Unveiling API 6A: A Game-Changer in Wellhead Technology

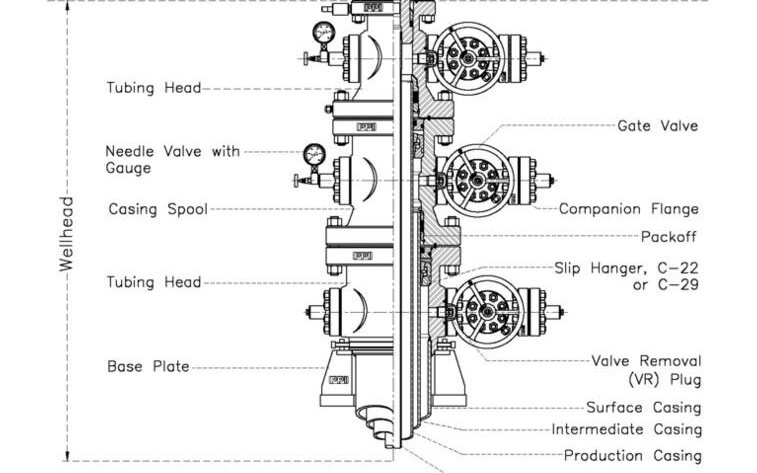

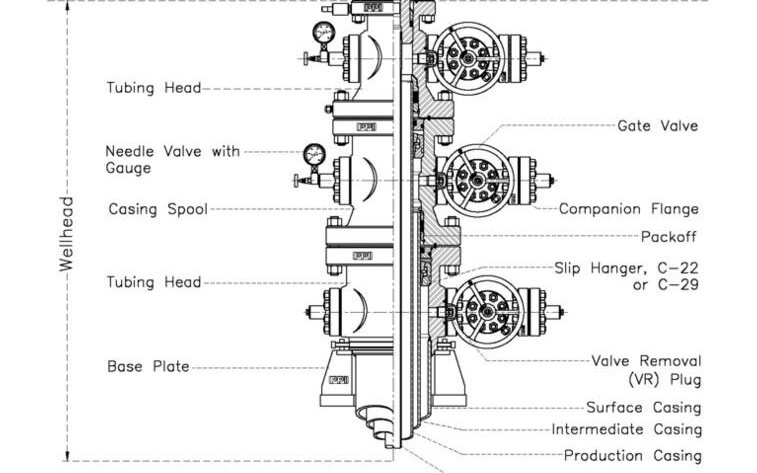

API 6A is not just a set of guidelines; it represents a comprehensive framework that defines the design, manufacturing, and testing specifications for wellhead equipment. This includes essential components such as wellhead housings, casing heads, tubing heads, valves, and associated gear. Engineered to withstand the challenging conditions of high pressures and temperatures inherent in oil and gas reservoirs, API 6A ensures robust and dependable wellhead systems.

Key Features that Redefine Wellhead Excellence

Shaping the Future of Oil and Gas Production

API 6A Wellhead Equipment stands as a testament to industry innovation, setting the stage for a new era in oil and gas extraction. Its adherence to rigorous standards not only guarantees operational excellence but also contributes significantly to the overall integrity of oil and gas production processes.

As the energy sector evolves, API 6A remains at the forefront, empowering industry professionals with cutting-edge technology and unwavering reliability. Embrace the future of wellhead excellence with API 6A.

Unveiling API 6A: A Game-Changer in Wellhead Technology

API 6A is not just a set of guidelines; it represents a comprehensive framework that defines the design, manufacturing, and testing specifications for wellhead equipment. This includes essential components such as wellhead housings, casing heads, tubing heads, valves, and associated gear. Engineered to withstand the challenging conditions of high pressures and temperatures inherent in oil and gas reservoirs, API 6A ensures robust and dependable wellhead systems.

Key Features that Redefine Wellhead Excellence

1. Versatile Wellhead Housing: At the summit of the wellhead assembly, the wellhead housing, often referred to as the "wellhead spool," serves as a central hub, providing seamless connections for other components while supporting the weight of casing strings.

2. Efficient Casing Head: Acting as a landing point for casing strings in the wellbore, the casing head not only facilitates the process but also ensures a secure seal in the annular space between the casing and the wellhead housing.

3. Reliable Tubing Head: Similar to the casing head, the tubing head offers a stable platform for tubing strings involved in the extraction of oil or gas, featuring seals that prevent leaks and enhance operational safety.

4. Diverse Valves: API 6A integrates various valve types, including gate valves, choke valves, and check valves, enabling precise control of fluid flow and the isolation of different sections within the well.

5. Innovative Christmas Tree Assembly: Positioned atop the wellhead, the Christmas tree assembly is a sophisticated mix of valves, gauges, and chokes, providing unparalleled control over production flow and facilitating essential operations such as testing, maintenance, and intervention.

6. Interconnected Flanges and Connections: API 6A introduces standardized flange designs and connection methods, ensuring seamless compatibility between diverse components and equipment.

7. Stringent Materials and Testing Protocols: Upholding a commitment to safety and reliability, API 6A mandates strict requirements for construction materials and comprehensive testing procedures, ensuring equipment integrity under extreme conditions.

2. Efficient Casing Head: Acting as a landing point for casing strings in the wellbore, the casing head not only facilitates the process but also ensures a secure seal in the annular space between the casing and the wellhead housing.

3. Reliable Tubing Head: Similar to the casing head, the tubing head offers a stable platform for tubing strings involved in the extraction of oil or gas, featuring seals that prevent leaks and enhance operational safety.

4. Diverse Valves: API 6A integrates various valve types, including gate valves, choke valves, and check valves, enabling precise control of fluid flow and the isolation of different sections within the well.

5. Innovative Christmas Tree Assembly: Positioned atop the wellhead, the Christmas tree assembly is a sophisticated mix of valves, gauges, and chokes, providing unparalleled control over production flow and facilitating essential operations such as testing, maintenance, and intervention.

6. Interconnected Flanges and Connections: API 6A introduces standardized flange designs and connection methods, ensuring seamless compatibility between diverse components and equipment.

7. Stringent Materials and Testing Protocols: Upholding a commitment to safety and reliability, API 6A mandates strict requirements for construction materials and comprehensive testing procedures, ensuring equipment integrity under extreme conditions.

Shaping the Future of Oil and Gas Production

API 6A Wellhead Equipment stands as a testament to industry innovation, setting the stage for a new era in oil and gas extraction. Its adherence to rigorous standards not only guarantees operational excellence but also contributes significantly to the overall integrity of oil and gas production processes.

As the energy sector evolves, API 6A remains at the forefront, empowering industry professionals with cutting-edge technology and unwavering reliability. Embrace the future of wellhead excellence with API 6A.