Key Advantages and Common Types of Plug Valves

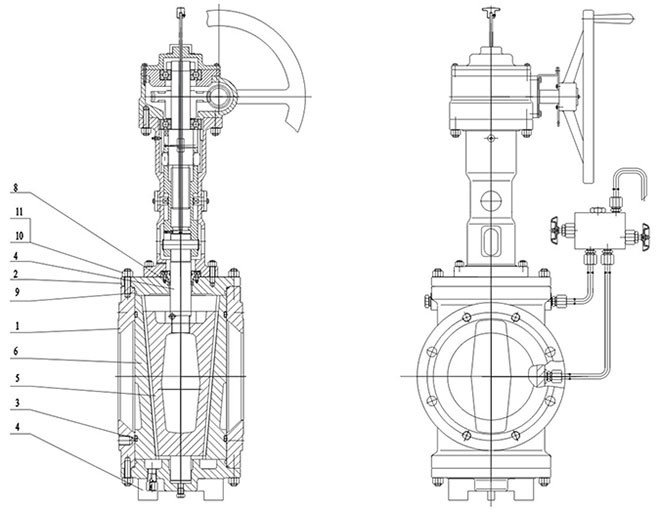

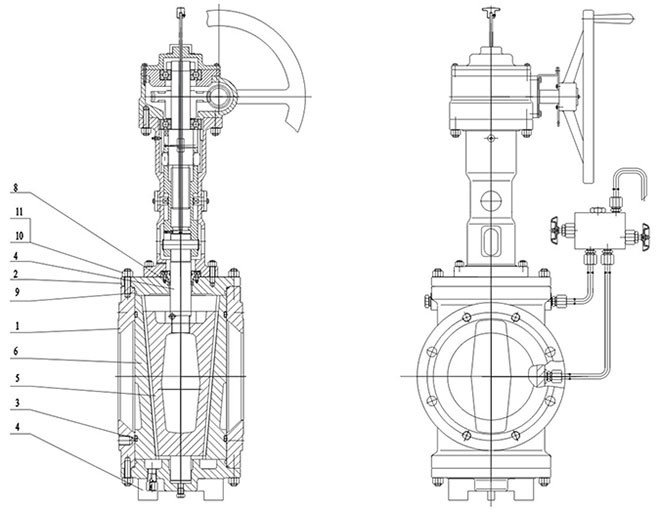

In a significant stride forward in valve engineering, the plug valves have emerged as a groundbreaking solution, effortlessly opening or closing with just a 90-degree rotation, aligning or separating the flow passages on the plug and valve body.

The plug in a plug valve can take the shape of a cylinder or a cone. In cylindrical plugs, the flow passage is typically rectangular, while in conical plugs, it adopts a trapezoidal form. These evolving shapes contribute to the lightweight structure of plug valves, albeit with some associated losses.

Perfectly suited for cutoffs, interceptions, and diverting applications, plug valves can also be employed for throttling, depending on the nature of the application and the corrosion resistance of the sealing surface. A clockwise rotation aligns the grooves parallel to the pipe, whereas a counterclockwise rotation of 90 degrees positions the grooves perpendicular to the pipe.

Key Advantages of Plug Valves

Exploring Different Types of Plug Valves

Structurally, plug valves are classified into four types: tight-fitting, self-sealing, packing-filled, and oil-spray. Channel-wise, they can be categorized as straight-through, three-way, and four-way.

1. Packing-Filled Plug Valve

This type achieves sealing by compressing filling material between the plug body and the valve body. The presence of packing ensures excellent sealing performance. Typically featuring a packing cover, this valve eliminates the need for the plug to extend beyond the valve body, reducing potential leakage paths. It finds extensive use in pn1mpa pressure applications.

2. Self-Sealing Plug Valve

Operating through the pressure of the medium itself, this valve achieves compression sealing between the plug and plug body. The smaller end of the plug extends upward, allowing the medium to enter through the small inlet hole into the larger end of the plug, exerting upward pressure on the plug. This structure is commonly used for air media.

3. Oil-Sealed Plug Valve

In recent years, the application range of plug valves has expanded, giving rise to the oil-sealed plug valve with forced lubrication. This design forms an oil film between the sealing surfaces of the plug and valve body, resulting in improved sealing performance, effortless opening and closing, and protection against surface damage.

These advancements in plug valve technology mark a significant leap forward, promising enhanced efficiency and durability across diverse applications. The introduction of various types and configurations underscores their adaptability to different operational requirements, solidifying their status as a crucial component in fluid control systems.

The plug in a plug valve can take the shape of a cylinder or a cone. In cylindrical plugs, the flow passage is typically rectangular, while in conical plugs, it adopts a trapezoidal form. These evolving shapes contribute to the lightweight structure of plug valves, albeit with some associated losses.

Perfectly suited for cutoffs, interceptions, and diverting applications, plug valves can also be employed for throttling, depending on the nature of the application and the corrosion resistance of the sealing surface. A clockwise rotation aligns the grooves parallel to the pipe, whereas a counterclockwise rotation of 90 degrees positions the grooves perpendicular to the pipe.

Key Advantages of Plug Valves

- Ideal for frequent operations, rapid opening and closing, and lightweight scenarios.

- Low fluid resistance.

- Simple structure, relatively small size, lightweight, and easy maintenance.

- Excellent sealing performance.

- Unrestricted by installation orientation; fluid flow direction can be arbitrary.

- Minimal vibration and low noise.

Exploring Different Types of Plug Valves

Structurally, plug valves are classified into four types: tight-fitting, self-sealing, packing-filled, and oil-spray. Channel-wise, they can be categorized as straight-through, three-way, and four-way.

1. Packing-Filled Plug Valve

This type achieves sealing by compressing filling material between the plug body and the valve body. The presence of packing ensures excellent sealing performance. Typically featuring a packing cover, this valve eliminates the need for the plug to extend beyond the valve body, reducing potential leakage paths. It finds extensive use in pn1mpa pressure applications.

2. Self-Sealing Plug Valve

Operating through the pressure of the medium itself, this valve achieves compression sealing between the plug and plug body. The smaller end of the plug extends upward, allowing the medium to enter through the small inlet hole into the larger end of the plug, exerting upward pressure on the plug. This structure is commonly used for air media.

3. Oil-Sealed Plug Valve

In recent years, the application range of plug valves has expanded, giving rise to the oil-sealed plug valve with forced lubrication. This design forms an oil film between the sealing surfaces of the plug and valve body, resulting in improved sealing performance, effortless opening and closing, and protection against surface damage.

These advancements in plug valve technology mark a significant leap forward, promising enhanced efficiency and durability across diverse applications. The introduction of various types and configurations underscores their adaptability to different operational requirements, solidifying their status as a crucial component in fluid control systems.