Slow Closing Check Valves: Enhancing Pipeline Integrity

Slow Closing Check Valves play a crucial role in maintaining the integrity of pipelines by preventing the backflow of media. This article explores the structural features, maintenance practices, and installation guidelines for these check valves, emphasizing their significance in ensuring efficient, safe, and reliable pipeline systems.

The Structural Features of Slow Closing Check Valve

Slow Closing Check Valves exhibit distinctive structural features that contribute to their efficiency and reliability. Here is an in-depth look at the key structural characteristics of these valves:

The Maintenance Guideline

Installation and Usage

In conclusion, the implementation of Slow Closing Check Valves significantly enhances the reliability and safety of pipeline systems. Their unique structural features, coupled with proper maintenance and installation practices, make these valves indispensable in preventing backflow and ensuring the smooth operation of pipelines. As critical components in pipeline integrity, Slow Closing Check Valves contribute to the overall efficiency and longevity of fluid transport systems.

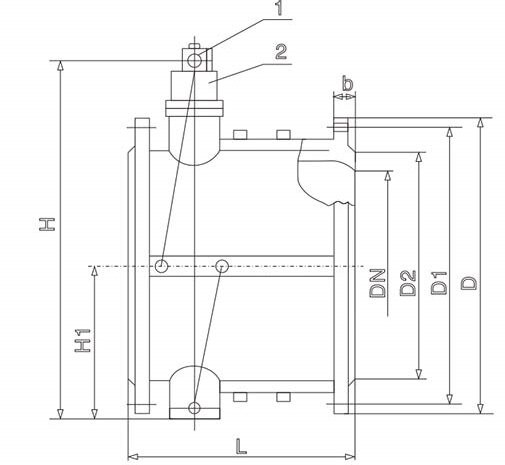

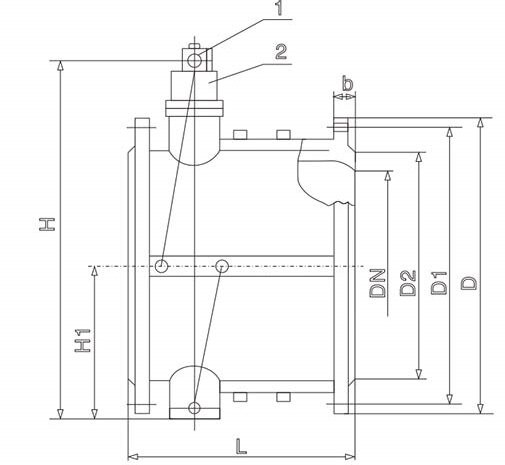

The Structural Features of Slow Closing Check Valve

Slow Closing Check Valves exhibit distinctive structural features that contribute to their efficiency and reliability. Here is an in-depth look at the key structural characteristics of these valves:

1. Compact Design: Boasting a structural length only 1/4~1/8 of traditional valves, they save space and allow flexible installation.

2. Lightweight Construction: These valves are small and lightweight, weighing only 1/4~1/20 of traditional valves, facilitating easy handling during installation and maintenance.

3. Quick Closure: The valve disc rapidly closes, minimizing water hammer pressure, enhancing backflow prevention, and reducing pressure fluctuations.

4. Versatile Installation: Suitable for horizontal and vertical pipelines, they provide installation versatility, simplifying integration into various systems.

5. Smooth Flow Passage: With a smooth flow passage, these valves minimize fluid resistance, ensuring efficient fluid flow and optimal system performance.

6. Sensitive Operation and Sealing: Known for sensitive operation, they respond promptly to changes in media flow and exhibit excellent sealing performance to prevent undesired backflow.

7. Short Valve Disc Stroke: Featuring a short valve disc stroke, these valves minimize impact force during closure, enhancing durability and reducing wear over time.

8. Simple and Compact Structure: The valves have a simple and compact structure, contributing to ease of installation and maintenance with an aesthetically pleasing design.

9. Long Service Life and Reliability: Designed for longevity and high reliability, their durable construction and robust materials ensure a dependable component in pipeline systems.

2. Lightweight Construction: These valves are small and lightweight, weighing only 1/4~1/20 of traditional valves, facilitating easy handling during installation and maintenance.

3. Quick Closure: The valve disc rapidly closes, minimizing water hammer pressure, enhancing backflow prevention, and reducing pressure fluctuations.

4. Versatile Installation: Suitable for horizontal and vertical pipelines, they provide installation versatility, simplifying integration into various systems.

5. Smooth Flow Passage: With a smooth flow passage, these valves minimize fluid resistance, ensuring efficient fluid flow and optimal system performance.

6. Sensitive Operation and Sealing: Known for sensitive operation, they respond promptly to changes in media flow and exhibit excellent sealing performance to prevent undesired backflow.

7. Short Valve Disc Stroke: Featuring a short valve disc stroke, these valves minimize impact force during closure, enhancing durability and reducing wear over time.

8. Simple and Compact Structure: The valves have a simple and compact structure, contributing to ease of installation and maintenance with an aesthetically pleasing design.

9. Long Service Life and Reliability: Designed for longevity and high reliability, their durable construction and robust materials ensure a dependable component in pipeline systems.

The Maintenance Guideline

- Store the valve in a dry and well-ventilated indoor environment to prevent moisture, rain, and rust.

- During storage and transportation, close the valve disc, block both ends of the diameter with foam boards, tightly seal the ports with cover caps to prevent dust and rust.

- Provide appropriate packaging protection, shock absorption, and collision prevention for the cylinder part.

- Ensure stable placement of the valve, with the pneumatic driving device facing upward to avoid mutual squeezing.

- Periodically inspect the valve for dirt and rust on the flow passages and sealing surfaces every three months. Wipe off dirt and rust, and reapply rust-proof oil for protection.

Installation and Usage

- Install the slow closing check valve vertically on horizontal pipelines, with the valve generally in the fully open position during use.

- Prior to installation, remove the cover caps and foam boards from both ends of the valve passage, clean the internal cavity, and eliminate grease.

- Peel off the oil paper from the valve disc surface and remove any grease on the valve disc.

- During installation, ensure the restricted flow direction of the media.

- Media passing through the pipeline should not contain hard particles to prevent damage to the sealing surface.

- Each valve should undergo inspection and pass the required tests before leaving the factory. Installation units can conduct pressure tests directly or perform tests after installation.

In conclusion, the implementation of Slow Closing Check Valves significantly enhances the reliability and safety of pipeline systems. Their unique structural features, coupled with proper maintenance and installation practices, make these valves indispensable in preventing backflow and ensuring the smooth operation of pipelines. As critical components in pipeline integrity, Slow Closing Check Valves contribute to the overall efficiency and longevity of fluid transport systems.