High Pressure Seal Bonnet Gate Valve, ASTM A217 WC6, 2500 LB

Key Specifications / Features

Model No.: JSC-231124-CSGAV-53

Hits: 69

Are you in need of a High Pressure Seal Bonnet Gate Valve Supplier? Look no further. Our valves, crafted from Alloy Steel ASTM A217 WC6, are designed to withstand high pressures, rated at Class 2500 LB. Conforming to API 600 and API 6D standards, these valves offer manual operation through Handwheel or Gear mechanisms, ensuring robust and reliable performance. Available in sizes ranging from 2 to 40 inches, our valves are your solution for high-pressure applications.

Request a quote

Tags

Detail Information

High pressure seal bonnet gate valve

1. Type: PSB Gate Valves

2. Pressure Seal Bonnet (PSB), Flexible Wedge Design

3. Size Range: 2 Inch to 40 Inch

4. Pressure Ratings: ANSI 2500 LB

5. Materials Available in: Alloy Steel ASTM A217 WC6, Other materials available

6. Various trim materials are available to suit different service conditions

7. Actuator: Manual, Handwheel, Gear Operated

8. Special Requirement: Nace Mr 0175

Application:

Oil and Gas, Petrochemical, Power, Energy Industry etc.

Standards Design and Manufacture: Cast steel gate valve to API 600 or API 6D,

Inspection and Test: API 598, API 600 or API 6D.

End flange dimension: ASME B16.5 (for NPS≤24)

BW end dimension: ASME B16.25.

Face to face and end to end: ASME B16.10.

Pressure-temperature ratings: ASME B16.34.

Features:

1. Bonnet Gasket Style

Pressurized seal design is used for Class 2500 gate valve.

2. Packing Seal

As usual, flexible graphite is used for packing material. PTFE or combined packing material can be also used if being requosted by the customer.

3. Body and Bonnet Connection

Class 2500 gate valves usually adopt pressure seal bonnet design

4. Seat

For carbon steel gate valve, the seat is usually forged steel. The seat sealing surface is overlaying welded with hard alloy specified by the customer. For Stainless steel gate valve, the seat is integral with body, or it can be machined directly after hard alloy welded.

5. Disc Design

NPS ≥ 2 Gate valves are flexible wedge gate.

6. Backseat Design

All gate valves have backseat design. In most cases,the carbon steel gate valve is fitted with a renewable back seat. For stainless steel gate valve, the back seat is machined directly in the bonnet or be machined after welding.

7. Stem Design

The stem is integral forged design. The minimum diameter of the stem shall be as per the standard requirement.

8 .Stem Nut

Usually, the stem nut is made of ASTM A439 D2. It is also can be made of copper alloy or other materials if being requested by the customer.

9. Operation

Hand wheel or bevel gear box is usually used for gate valve operation.

Description:

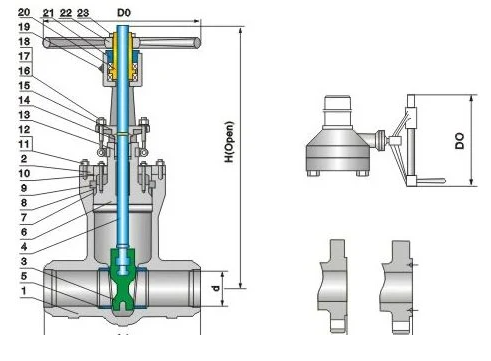

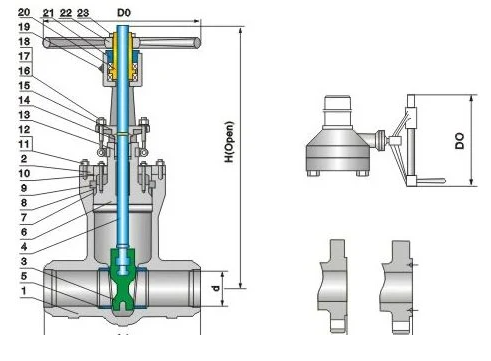

1. Pressure Seal Bonnet Cast Steel Gate Valve Parts and Material List for Class 2500LB:

1. Type: PSB Gate Valves

2. Pressure Seal Bonnet (PSB), Flexible Wedge Design

3. Size Range: 2 Inch to 40 Inch

4. Pressure Ratings: ANSI 2500 LB

5. Materials Available in: Alloy Steel ASTM A217 WC6, Other materials available

6. Various trim materials are available to suit different service conditions

7. Actuator: Manual, Handwheel, Gear Operated

8. Special Requirement: Nace Mr 0175

Application:

Oil and Gas, Petrochemical, Power, Energy Industry etc.

Standards Design and Manufacture: Cast steel gate valve to API 600 or API 6D,

Inspection and Test: API 598, API 600 or API 6D.

End flange dimension: ASME B16.5 (for NPS≤24)

BW end dimension: ASME B16.25.

Face to face and end to end: ASME B16.10.

Pressure-temperature ratings: ASME B16.34.

Features:

1. Bonnet Gasket Style

Pressurized seal design is used for Class 2500 gate valve.

2. Packing Seal

As usual, flexible graphite is used for packing material. PTFE or combined packing material can be also used if being requosted by the customer.

3. Body and Bonnet Connection

Class 2500 gate valves usually adopt pressure seal bonnet design

4. Seat

For carbon steel gate valve, the seat is usually forged steel. The seat sealing surface is overlaying welded with hard alloy specified by the customer. For Stainless steel gate valve, the seat is integral with body, or it can be machined directly after hard alloy welded.

5. Disc Design

NPS ≥ 2 Gate valves are flexible wedge gate.

6. Backseat Design

All gate valves have backseat design. In most cases,the carbon steel gate valve is fitted with a renewable back seat. For stainless steel gate valve, the back seat is machined directly in the bonnet or be machined after welding.

7. Stem Design

The stem is integral forged design. The minimum diameter of the stem shall be as per the standard requirement.

8 .Stem Nut

Usually, the stem nut is made of ASTM A439 D2. It is also can be made of copper alloy or other materials if being requested by the customer.

9. Operation

Hand wheel or bevel gear box is usually used for gate valve operation.

Description:

1. Pressure Seal Bonnet Cast Steel Gate Valve Parts and Material List for Class 2500LB:

| Parts No. | Parts Name | Materials | |

| WCB/Trim 5 | WC6/Trim 5 | ||

| 1 | Body | ASTM A216 WCB | ASTM A217 WC6 |

| 2 | Yoke | ASTM A216 WCB | ASTM A217 WC6 |

| 3 | Gate | ASTM A216 WCB +STL | ASTM A217 WC6 + STL |

| 4 | Stem | ASTM A182 F6a | ASTM A182 F6a |

| 5 | Seat Ring | ASTM A105 + STL | ASTM A182-F11 + STL |

| 6 | Bonnet | ASTM A216 WCB | ASTM A217 WC6 |

| 7 | Gasket | 304 + Graphite | |

| 8 | Adapter Ring | Carbon Steel | Alloy Steel |

| 9 | Retainer | Carbon Steel | Alloy Steel |

| 10 | Yoke Cap | Carbon Steel | Alloy Steel |

| 11 | Bonnet Stud | ASTM A193 B7 | ASTM A193 B16 |

| 12 | Bonnet Stud Nut | ASTM A194 2H | ASTM A194 7 |

| 13 | Packing | Graphite | |

| 14 | Gland | ASTM A182F6a | ASTM A182F6a |

| 15 | Gland Flange | ASTM A216 WCB | ASTM A217 WC6 |

| 16 | Eyebolt Pin | ASTM A36 | ASTM A36 |

| 17 | Eyebolt | ASTMA193 B7 | ASTM A193 B7 |

| 18 | Eyebolt Nut | ASTM A194 2H | ASTM A194 2H |

Comment Form