ASTM A182 F304 Swing Check Valve, API 602, 1 Inch, CL 800 LB

Key Specifications / Features

Model No.: JSC-240409-SCV-01

Hits: 155

Crafted from high-quality forged stainless steel, ASTM A182 F304, in strict accordance with API 602 standards, our swing check valve offers reliable performance. With a compact 1-inch size and a robust pressure rating of Class 800 LB, it ensures efficient flow control and durability, featuring convenient NPT ends for easy installation in various industrial applications.

Request a quote

Tags

Detail Information

Forged Swing Check Valve

Body material: ASTM A182 F304

Nominal diameter: 1 Inch (DN25)

Nominal class: Class 800 LB (PN150)

End connection: NPT

Metal seat: 304

Standard: API 602

Face to face: MFR, API 602

Test and inspection: API 598

The Forged steel check valve operates by utilizing the flow of the medium itself to automatically open and close the valve disc. It serves the purpose of preventing the reverse flow of the medium and is commonly referred to as a check valve, one-way valve, reverse flow valve, or back pressure valve. Additionally, the body guide ensures alignment of the seat and disc. When the piston check valve closes, the flow pressure will force the disc to lift off the seat, allowing fluid to pass through the valve.

Forged Steel Swing Check Valve-Features

1. The body is forged steel and available in reduced and full bore design

2. Bolted bonnet, Welded Bonnet or Pressure Seal Bonnet

3. Spring loaded piston

4. Integral seat

Forged Steel Swing Check Valve - Specifications and Standards

1. Design standard: API 602, ASME 16.34

2. Pressure temperature standard: ASME 16.34

3. Face to face dimension: MFR Standard

4. Testing and inspection standard: API 598

5. Flanged Ends: ASME B16.5

6. Butt Welded Ends: ASME B16.25

7. Screwed Ends: ASME B1.20.1

8. Socket Welded Ends: ASME B16.11

9. Ends: Flanged ends, Socket Weld End, Screwed End, Butt-weld end

10. Size range: 1/2 Inch - 3 Inch (DN15-DN80)

11. Pressure Range: Class 150 LB, 300 LB, 600 LB, 900 LB, 1500 LB, 2500 LB, 4500 LB

12. Body material: ASTM A105N, ASTM A350 LF2, ASTM A182 F5, ASTM A182 F22, ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F347, ASTM A182 F321, ASTM A182 F51, ASTM A182 F55, Inconel Alloy, Monel Alloy, Hastelloy Alloy.

13. Trim material: ASTM A182 F6a, F316, F304, F316L, F321, F51, F55, Inconel, Stellied or Hardfaced

Swing Check Valve Class 800 LB, 900 – 1500 LB - Standard Material Specifications

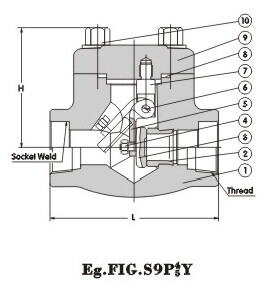

| NO. | Part Name | CS to ASTM | AS to ASTM | SS to ASTM | |

| Type A105 | Type F22 | Type F304 (L) | Type F316 (L) | ||

| 1 | Body | A105 | A182 F22 | A182 F304 (L) | A182 F316 (L) |

| 2 | Seat | A276 410 | A276 304 | A276 304 (L) | A276 316 (L) |

| 3 | Swing Disc | A276 420 | A276 304 | A276 304 (L) | A276 316 (L) |

| 4 | Nut | A194 2H | A194 4 | A194 8 | A194 8M |

| 5 | Hinge | A105 | A182 F22 | A182 F304 L | A182 F316(L) |

| 6 | Pin | A276 420 | A182 F304 | A182 F316 | |

| 7 | Pontlevis | A105 | A182 F22 | A182 F304 L | A182 F316(L) |

| 8 | Gasket | Corrugated SS + graphite | SS + PTFE | ||

| 9 | Bonnet | A105 | A182 F22 | A182 F304 L | A182 F316(L) |

| 10 | Bolt | A193 B7 | A193 B16 | A193 B8M | A193 B8M |

| Suitable Medium | W.O.G.etc | W.O.G.etc | HNO3, CH3OOH etc | ||

| Suitable Temperature | -29 425 | -29 550 | -29 180 | ||

Note: Other materials are available upon request.

Dimensions (mm) and Weights (Kg)

| NPS | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | |

| L | 80 LB | 79 | 79 | 92 | 111 | 120 | 120 | 140 |

| 900 - 1500 LB | 92 | 111 | 111 | 120 | 120 | 140 | 178 | |

| H | 800 LB | 61 | 61 | 78 | 84 | 101 | 120 | 133 |

| 900 - 1500 LB | 79 | 79 | 79 | 97 | 105 | 120 | 140 | |

| Weights | 800 LB | 1.1 | 1.0 | 1.9 | 3.9 | 4.5 | 7.3 | 10.0 |

| 900 - 1500 LB | 3.1 | 3.0 | 3.6 | 4.3 | 6.1 | 8.8 | 12.6 | |

Comment Form