Working Principle and Characteristics of Three-Way Ball Valves

Fluid control systems rely on efficient valves, and three-way ball valves, particularly the T-type and L-type variants, play a pivotal role. This section explores their working principles and characteristics, crucial for understanding their diverse applications and advantages across industries. Let's delve into the unique features that make threse ball valves indispensable in fluid management.

I. Three-Way Ball Valve Types

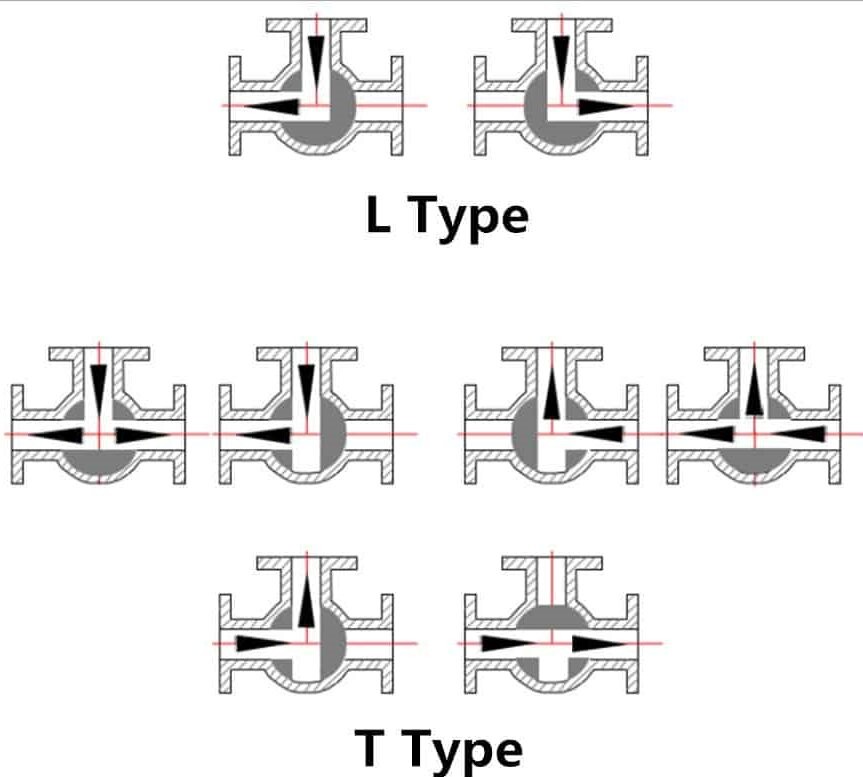

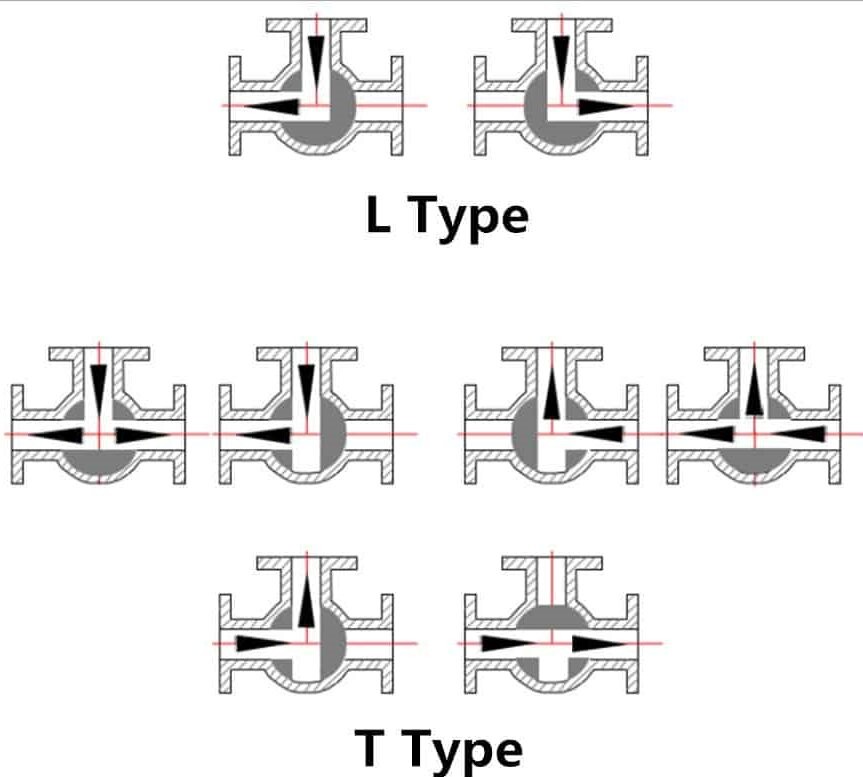

Three-way ball valves come in two main types: T-type and L-type. The T-type allows for the interconnection and cutoff of three orthogonal pipelines, serving the purpose of diversion and convergence. On the other hand, the L-type can only connect two mutually orthogonal pipelines at a time, unable to maintain the simultaneous interconnection of the third pipeline, functioning solely for distribution.

II. Characteristics and Advantages

Three-way ball valves possess several characteristics and advantages that make them widely preferred in various applications:

III. Opening and Closing Process and Working Principle

Opening Process: In the closed position, the ball is tightly pressed against the seat through mechanical pressure. Rotating the handwheel counterclockwise moves the stem, separating the ball from the seat. As the stem continues to rise, the ball rotates frictionlessly until it reaches the fully open position.

Closing Process: Rotating the handwheel clockwise lowers the stem, causing the ball to rotate after leaving the seat. Continuing to rotate the handwheel, the stem and ball simultaneously rotate 90°. Near closure, the ball has rotated 90° without contact. In the final few turns of the handwheel, the bottom angular plane of the stem mechanically wedges to compress the ball tightly against the seat, achieving complete sealing.

In summary, the working principle of three-way ball valves determines that the valve body has three ports, allowing for one inlet and two outlets or vice versa. Unlike conventional valves, different outlet passages are connected when the internal valve core is in different positions, providing flexibility for various operations and controls.

I. Three-Way Ball Valve Types

Three-way ball valves come in two main types: T-type and L-type. The T-type allows for the interconnection and cutoff of three orthogonal pipelines, serving the purpose of diversion and convergence. On the other hand, the L-type can only connect two mutually orthogonal pipelines at a time, unable to maintain the simultaneous interconnection of the third pipeline, functioning solely for distribution.

II. Characteristics and Advantages

Three-way ball valves possess several characteristics and advantages that make them widely preferred in various applications:

Low Fluid Resistance: The resistance coefficient is equivalent to that of the same length of pipeline, ensuring smooth fluid flow.

Simple Structure, Compact Size, Light Weight: Easy to install and maintain, suitable for spaces with different constraints.

Tight and Reliable, Excellent Sealing: Efficient leakage prevention, ensuring the safety of system operation.

Wide Application Range: With diameters ranging from a few millimeters to several meters, applicable in conditions ranging from high vacuum to high pressure.

Convenient Operation, Quick Opening and Closing: Rotating 90° opens or closes the valve rapidly, facilitating remote control.

Easy Maintenance: Simple structure, generally with movable sealing rings, facilitating convenient disassembly and replacement.

Simple Structure, Compact Size, Light Weight: Easy to install and maintain, suitable for spaces with different constraints.

Tight and Reliable, Excellent Sealing: Efficient leakage prevention, ensuring the safety of system operation.

Wide Application Range: With diameters ranging from a few millimeters to several meters, applicable in conditions ranging from high vacuum to high pressure.

Convenient Operation, Quick Opening and Closing: Rotating 90° opens or closes the valve rapidly, facilitating remote control.

Easy Maintenance: Simple structure, generally with movable sealing rings, facilitating convenient disassembly and replacement.

III. Opening and Closing Process and Working Principle

Opening Process: In the closed position, the ball is tightly pressed against the seat through mechanical pressure. Rotating the handwheel counterclockwise moves the stem, separating the ball from the seat. As the stem continues to rise, the ball rotates frictionlessly until it reaches the fully open position.

Closing Process: Rotating the handwheel clockwise lowers the stem, causing the ball to rotate after leaving the seat. Continuing to rotate the handwheel, the stem and ball simultaneously rotate 90°. Near closure, the ball has rotated 90° without contact. In the final few turns of the handwheel, the bottom angular plane of the stem mechanically wedges to compress the ball tightly against the seat, achieving complete sealing.

In summary, the working principle of three-way ball valves determines that the valve body has three ports, allowing for one inlet and two outlets or vice versa. Unlike conventional valves, different outlet passages are connected when the internal valve core is in different positions, providing flexibility for various operations and controls.