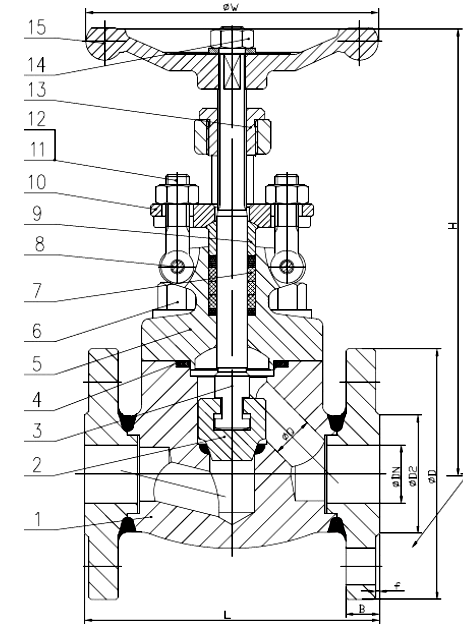

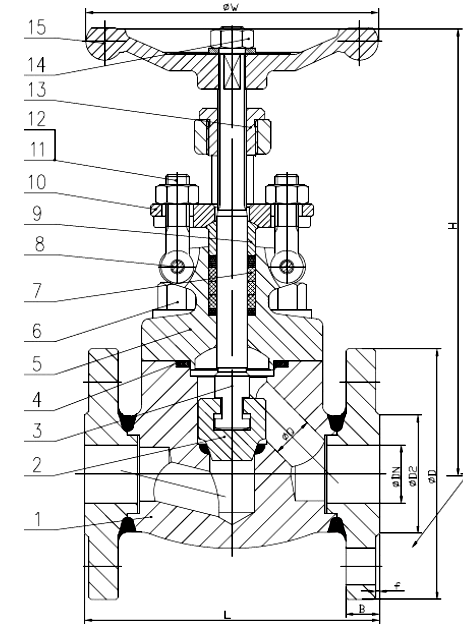

Forged Steel Globe Valve: Features, Applications and Maintenance Guide

A forged steel globe valve is a common type of valve, typically made from forged steel material through the process of forging. It serves as a valve for controlling the flow of fluids, allowing for opening, closing, or regulating fluid passages. Here is detailed information about the features, applications, and maintenance of forged steel globe valves.

Features of Forged Steel Globe Valve

Forged steel globe valves possess the following features, making them widely used in specific applications:

Versatility of Forged Steel Globe Valve

Forged steel globe valves find widespread applications across various industries, including but not limited to:

Forged steel globe valves, with their excellent sealing performance, flow characteristics, and high-temperature/high-pressure capabilities, are widely used in pipeline systems across multiple industries.

Maintenance and Care Guide

To ensure the long-term use and optimal performance of forged steel globe valves, the following maintenance steps are recommended:

In summary, forged steel globe valves, designed for high-temperature and high-pressure conditions, are crucial in power plants, chemical, petroleum, pharmaceutical, hydraulic, agricultural, and industrial pipelines. Regular checks on sealing, lubrication, cleaning, and environmental factors are vital for optimal performance. They play a key role in fluid control across diverse sectors.

Features of Forged Steel Globe Valve

Forged steel globe valves possess the following features, making them widely used in specific applications:

High Temperature and Pressure: Forged steel material exhibits excellent pressure resistance, suitable for high-temperature and high-pressure conditions.

Self-Sealing Design: Utilizes a unique self-sealing design, providing more reliable sealing performance with increasing pressure.

Low Flow Resistance: Interconnected valve body structure minimizes fluid resistance.

Excellent Sealing Performance: Sealing performance of forged steel surpasses emergency shut-off valves, with convenient open-close operations.

Wide Range of Applications: Suitable for non-corrosive media like water and steam, as well as solid particles, low-viscosity media, automatic air release valves, and low vacuum systems.

Self-Sealing Design: Utilizes a unique self-sealing design, providing more reliable sealing performance with increasing pressure.

Low Flow Resistance: Interconnected valve body structure minimizes fluid resistance.

Excellent Sealing Performance: Sealing performance of forged steel surpasses emergency shut-off valves, with convenient open-close operations.

Wide Range of Applications: Suitable for non-corrosive media like water and steam, as well as solid particles, low-viscosity media, automatic air release valves, and low vacuum systems.

Versatility of Forged Steel Globe Valve

Forged steel globe valves find widespread applications across various industries, including but not limited to:

Power Plants: Used in piping systems to cut off or connect water, steam, and other media.

Chemical Industry: Applicable to various corrosive and non-corrosive media, such as nitric acid, acetic acid, and oxidative media.

Petroleum and Metallurgical Industry: Employed in the transportation systems of oil, gas, and other media.

Pharmaceutical Industry: Suitable for various media, including pharmaceutical solutions and bio-products.

Hydraulic Engineering: Applied in hydropower generation, water supply and drainage, urban gas, etc.

Agricultural Irrigation: Used in field irrigation and garden spraying systems.

Industrial Pipelines: Suitable for medium cut-off and control in various industrial pipeline systems.

Chemical Industry: Applicable to various corrosive and non-corrosive media, such as nitric acid, acetic acid, and oxidative media.

Petroleum and Metallurgical Industry: Employed in the transportation systems of oil, gas, and other media.

Pharmaceutical Industry: Suitable for various media, including pharmaceutical solutions and bio-products.

Hydraulic Engineering: Applied in hydropower generation, water supply and drainage, urban gas, etc.

Agricultural Irrigation: Used in field irrigation and garden spraying systems.

Industrial Pipelines: Suitable for medium cut-off and control in various industrial pipeline systems.

Forged steel globe valves, with their excellent sealing performance, flow characteristics, and high-temperature/high-pressure capabilities, are widely used in pipeline systems across multiple industries.

Maintenance and Care Guide

To ensure the long-term use and optimal performance of forged steel globe valves, the following maintenance steps are recommended:

Regular Inspection of Sealing Performance: Periodically check the sealing condition of the valve disc and seat, and replace sealing components as needed.

Periodic Lubrication of Moving Parts: Apply lubricating oil or grease regularly to the valve's moving parts to reduce wear, friction, noise, and maintain flexibility and stability.

Regular Cleaning of Valve Interior: Remove accumulated impurities, dirt, etc., to ensure clear internal passages. Use appropriate cleaning agents and tools, prioritizing safety.

Consideration of Operating Environment: As forged steel globe valves are often used in high-temperature, high-pressure conditions, avoid excessive temperatures or pressures that may damage the valve. Regularly inspect the surrounding working environment for normal conditions.

Establishing Regular Inspection and Maintenance Plans: Develop a reasonable inspection and maintenance plan, including checking the status of bolts, sealing components, valve cover, and stem. Adjust maintenance frequency and methods based on actual conditions.

Periodic Lubrication of Moving Parts: Apply lubricating oil or grease regularly to the valve's moving parts to reduce wear, friction, noise, and maintain flexibility and stability.

Regular Cleaning of Valve Interior: Remove accumulated impurities, dirt, etc., to ensure clear internal passages. Use appropriate cleaning agents and tools, prioritizing safety.

Consideration of Operating Environment: As forged steel globe valves are often used in high-temperature, high-pressure conditions, avoid excessive temperatures or pressures that may damage the valve. Regularly inspect the surrounding working environment for normal conditions.

Establishing Regular Inspection and Maintenance Plans: Develop a reasonable inspection and maintenance plan, including checking the status of bolts, sealing components, valve cover, and stem. Adjust maintenance frequency and methods based on actual conditions.

In summary, forged steel globe valves, designed for high-temperature and high-pressure conditions, are crucial in power plants, chemical, petroleum, pharmaceutical, hydraulic, agricultural, and industrial pipelines. Regular checks on sealing, lubrication, cleaning, and environmental factors are vital for optimal performance. They play a key role in fluid control across diverse sectors.