Understanding the Structure and Sealing Principle of Wafer Check Valves

A wafer check valve is a type of check valve used in piping systems to prevent backflow of fluids. It's called a "wafer" check valve because of its slim profile resembling a wafer. The wafer check valve is a fundamental component in various industrial and pipeline systems. Below, we delve into its structure, features, and sealing principle to provide a comprehensive understanding of its functionality and application scope.

Wafer Check Valve: Structure and Features

The wafer check valve is characterized by its streamlined structure and versatile features that contribute to efficient flow control and prevention of backflow. Let's delve into the key aspects of its design and functionality:

Sealing Principle of Wafer Check Valve

The sealing principle of a wafer check valve is fundamental to its operation, ensuring effective flow control and preventing backflow within a pipeline system. Below, we outline the sealing principle of a wafer check valve:

In summary, the wafer check valve, with its simplified design, versatile installation options, and efficient sealing mechanism, serves as a reliable component in industrial and pipeline systems. Whether in fluid control applications or backflow prevention scenarios, the wafer check valve offers optimal performance and reliability, contributing to the seamless operation of diverse engineering systems.

Wafer Check Valve: Structure and Features

The wafer check valve is characterized by its streamlined structure and versatile features that contribute to efficient flow control and prevention of backflow. Let's delve into the key aspects of its design and functionality:

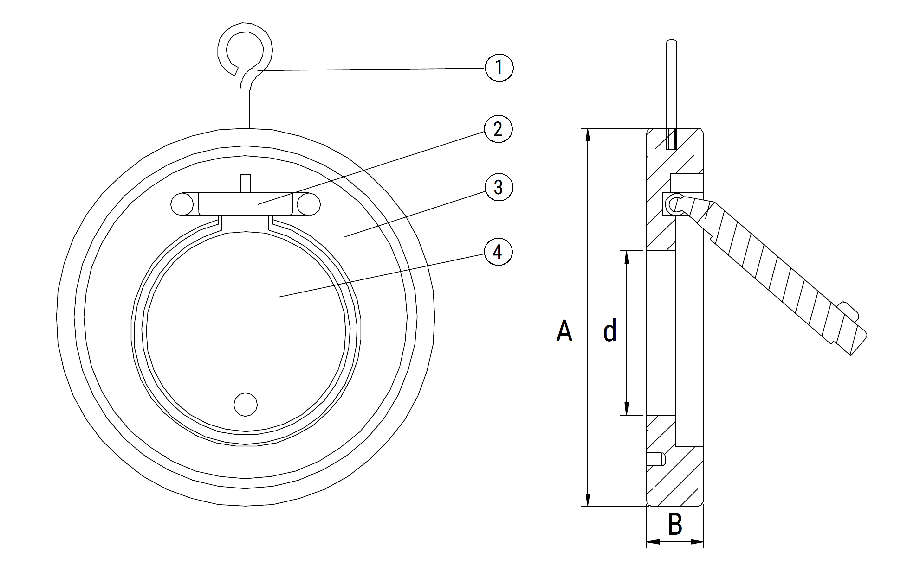

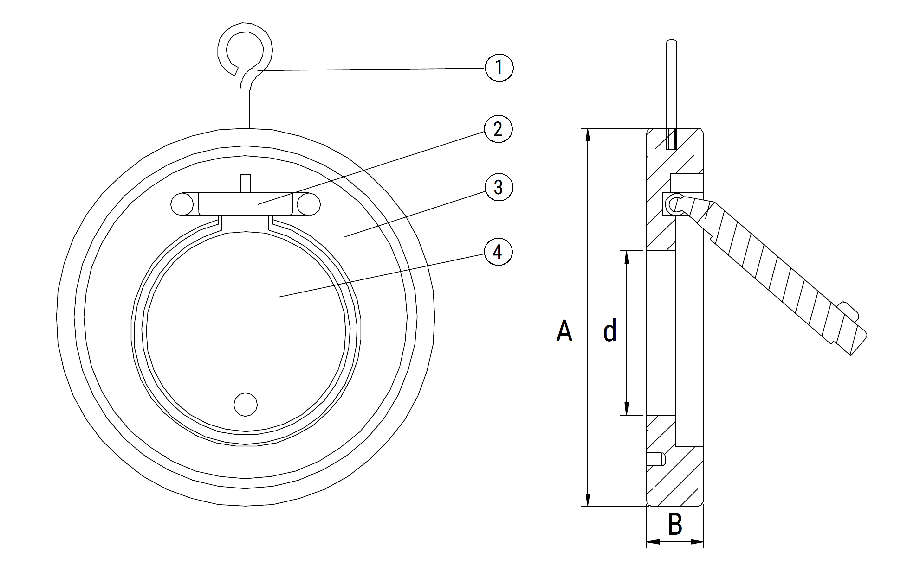

Simplified Design: The wafer check valve boasts a streamlined design, typically consisting of two semicircular disc components connected by a central shaft. This simplistic structure facilitates easy installation and maintenance.

Compact and Lightweight: Featuring a wafer-style configuration, this valve type exhibits a compact form factor and lightweight construction. It is well-suited for applications where space and weight considerations are crucial factors.

Versatile Installation: The wafer check valve's design allows for versatile installation options, including both vertical and horizontal orientations. This adaptability ensures compatibility with diverse pipeline configurations and requirements.

Low Flow Resistance: With minimal obstruction to fluid flow, the wafer check valve minimizes flow resistance within the pipeline, thereby enhancing overall system efficiency.

Compact and Lightweight: Featuring a wafer-style configuration, this valve type exhibits a compact form factor and lightweight construction. It is well-suited for applications where space and weight considerations are crucial factors.

Versatile Installation: The wafer check valve's design allows for versatile installation options, including both vertical and horizontal orientations. This adaptability ensures compatibility with diverse pipeline configurations and requirements.

Low Flow Resistance: With minimal obstruction to fluid flow, the wafer check valve minimizes flow resistance within the pipeline, thereby enhancing overall system efficiency.

Sealing Principle of Wafer Check Valve

The sealing principle of a wafer check valve is fundamental to its operation, ensuring effective flow control and preventing backflow within a pipeline system. Below, we outline the sealing principle of a wafer check valve:

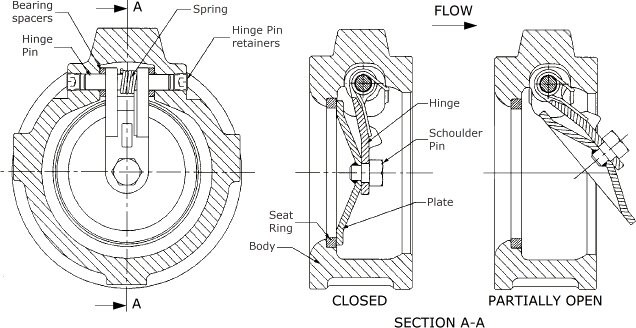

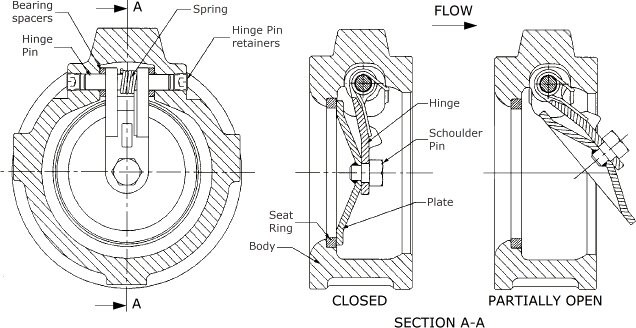

- Single Plate Wafer Check Valve: The sealing principle resembles that of a butterfly valve. During forward flow of the medium, the butterfly disc overcomes its own weight's torque through the medium's flow, opening the valve. Conversely, when the pump stops, the torque generated by the butterfly disc's own weight closes the valve. The sealing pressure produced by the medium's backflow achieves effective sealing.

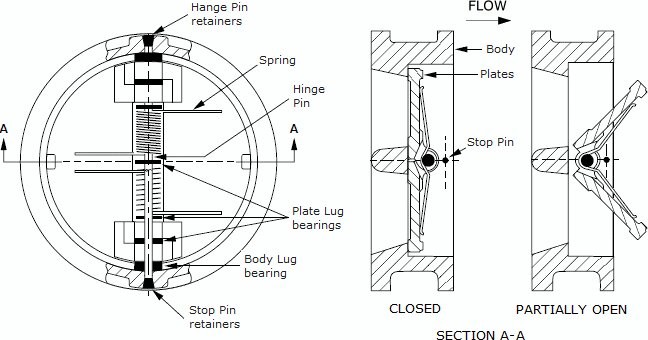

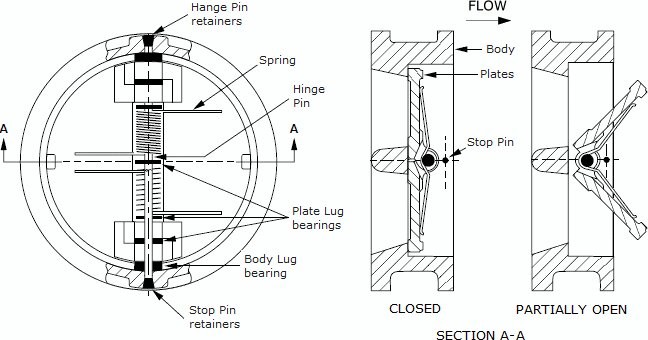

- Dual Plate Wafer Check Valve: The valve opens as the pressure from the medium's backflow overcomes the torque of the spring, while closing relies on the torque generated by the torsion spring. The sealing principle mirrors that of the single plate wafer check valve, where the width of the sealing surface is designed according to the working pressure of the medium to ensure sealing performance.

In summary, the wafer check valve, with its simplified design, versatile installation options, and efficient sealing mechanism, serves as a reliable component in industrial and pipeline systems. Whether in fluid control applications or backflow prevention scenarios, the wafer check valve offers optimal performance and reliability, contributing to the seamless operation of diverse engineering systems.