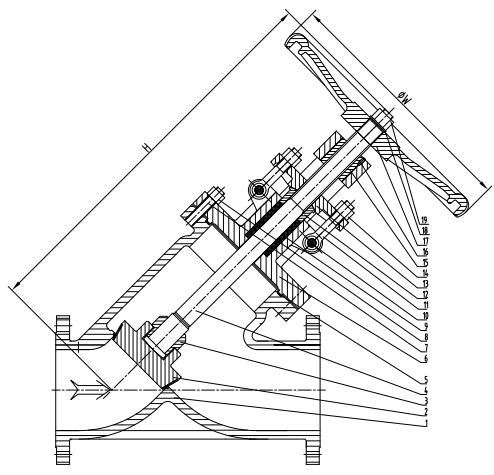

Optimizing Performance: Maintenance of Y-Pattern Globe Valves

Y-pattern globe valves, also referred to as gate valves, are crucial components in industrial settings, ensuring precise control and secure closure of fluid and gas flow. Operating on the principle of forced sealing, these globe valves play a vital role in maintaining operational efficiency and safety. However, ensuring their reliability and longevity requires meticulous maintenance. This article explores key maintenance practices for Y-pattern globe valves, covering inspection procedures, greasing operations, and pressure management techniques, aiming to optimize their performance and enhance industrial operations.

Critical Maintenance Points

a. Inspection of Valve and Related Components:

Thoroughly examine the integrity of flanges, support bracket bolts, threads, etc., to ensure steadfast connections.

Verify the secure fastening of handwheel locking nuts, packing gland covers, etc., to prevent issues arising from loosening.

Inspect the condition of the valve stem protective cover and scale for any damage to mitigate external environmental impacts on the valve.

b. Valve Maintenance Precautions:

Strictly prohibit knocking, standing on, or placing heavy loads on the valve during operations to avoid compromising the valve's structural integrity.

Exercise heightened vigilance in maintenance procedures for non-metallic and cast iron valves to prolong their operational lifespan.

c. Key Considerations for Greasing Operations:

Precisely control the amount of grease: Calculate the appropriate quantity based on the valve type and size to prevent under or over-greasing.

Adjust grease pressure accordingly: Regulate pressure in accordance with established patterns to ensure the efficacy and safety of greasing operations.

Thoroughly examine the integrity of flanges, support bracket bolts, threads, etc., to ensure steadfast connections.

Verify the secure fastening of handwheel locking nuts, packing gland covers, etc., to prevent issues arising from loosening.

Inspect the condition of the valve stem protective cover and scale for any damage to mitigate external environmental impacts on the valve.

b. Valve Maintenance Precautions:

Strictly prohibit knocking, standing on, or placing heavy loads on the valve during operations to avoid compromising the valve's structural integrity.

Exercise heightened vigilance in maintenance procedures for non-metallic and cast iron valves to prolong their operational lifespan.

c. Key Considerations for Greasing Operations:

Precisely control the amount of grease: Calculate the appropriate quantity based on the valve type and size to prevent under or over-greasing.

Adjust grease pressure accordingly: Regulate pressure in accordance with established patterns to ensure the efficacy and safety of greasing operations.

Addressing Pressure Concerns During Greasing

- Grease pressure fluctuation patterns: Typically characterized by peaks and troughs, necessitating careful monitoring to maintain pressure stability.

- Identification of issues stemming from low pressure: Address potential seal failures by making necessary adjustments based on observed conditions.

- Dealing with complications arising from high pressure: Promptly rectify problems like grease port blockages or seal hardening through timely pressure adjustments.

Effective maintenance practices are indispensable for ensuring the optimal performance and longevity of Y-pattern globe valves. Beyond routine inspections to ascertain the integrity of valves and associated components, meticulous control over greasing quantity and pressure is imperative. Furthermore, selecting the appropriate maintenance postures based on valve type and condition is essential for safeguarding the efficiency and safety of maintenance endeavors.