The Essential Role of Pneumatic Wafer Butterfly Valves

On this page

The pneumatic wafer butterfly valve is a critical component for effective fluid control. This valve's innovative design and functionality are instrumental in ensuring operational efficiency and reliability across a multitude of industries. This article delves into the structural features of the pneumatic wafer butterfly valve, its numerous advantages, and its extensive applications, illustrating why it is an indispensable asset in modern industrial processes.

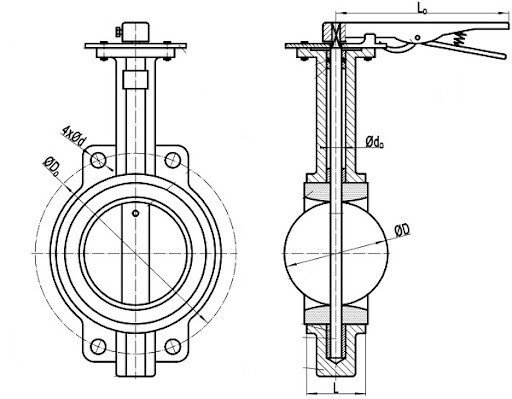

The design of the pneumatic wafer butterfly valve is intricately engineered to maximize its performance in industrial settings. Here, we explore the key components and characteristics that define its structural integrity and operational efficiency.

1. Pneumatic Actuator: The valve features a pneumatic piston-type actuator coupled with a triple eccentric metal hard-sealed butterfly valve body. The actuator's piston-type design delivers increased torque, flexible rotation, and a streamlined construction, ensuring reliable performance.

2. Butterfly Disc: Positioned along the pipeline diameter, the butterfly disc rotates smoothly within the valve body. It achieves a fully open position at a 90° angle, allowing for efficient flow control.

3. Versatile Valve Body: The valve body is designed to support various sealing configurations, including:

- Triple Eccentric Metal Sealing: Provides robust performance in demanding conditions.

- Tetrafluoroethylene (PTFE) Sealing: Offers excellent chemical resistance.

- Double Eccentric Soft Sealing: Ensures a tight seal and smooth operation.

The pneumatic wafer butterfly valve boasts numerous advantages, making it a preferred choice for fluid control in industrial environments. Key benefits of this butterfly valve will be discussed in details in the following parts.

1. Compact and Lightweight Design: The valve's simple structure, compact size, and lightweight nature facilitate easy installation and operation, leading to significant labor and time savings.

2. Rapid Operation: Its quick opening and closing capabilities make it ideal for applications requiring swift response times, thereby enhancing overall production efficiency.

3. Minimal Pressure Drop: When fully open, the valve ensures minimal pressure drop, showcasing exceptional flow control characteristics that meet stringent process requirements.

4. Adaptability: The availability of both elastic and metal sealing options allows the valve to handle a wide range of media and operating conditions, making it highly versatile.

5. Durability and Reliability: The valve's long service life, combined with its automatic sealing functionality, reduces maintenance costs and leakage risks, improving overall system reliability and stability.

The pneumatic wafer butterfly valve is widely utilized in various industries, offering reliable flow regulation and shut-off capabilities. Key applications include:

1. Ventilation and Environmental Protection: Commonly used in gas pipeline systems for ventilation and environmental protection in sectors such as chemicals, construction materials, power generation, and glass manufacturing.

2. High-Temperature and Low-Pressure Applications: Ideal for gas media with temperatures up to 300°C and nominal pressures of PN1, catering to diverse industrial processes.

The pneumatic wafer butterfly valve stands out as a technologically advanced solution, renowned for its superior structural design, operational efficiency, and versatility across a broad spectrum of industrial applications. Its seamless integration into pipeline systems optimizes industrial processes, yielding significant economic and societal benefits. As technology continues to advance, this valve is poised to further enhance operational efficacy in various industrial domains.