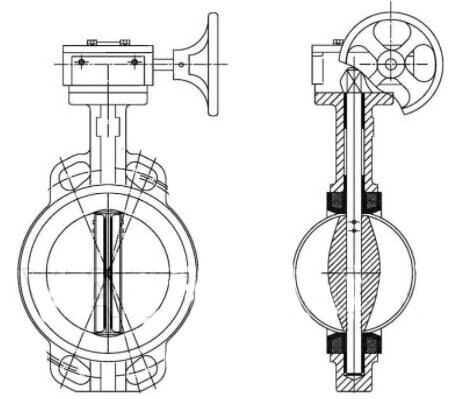

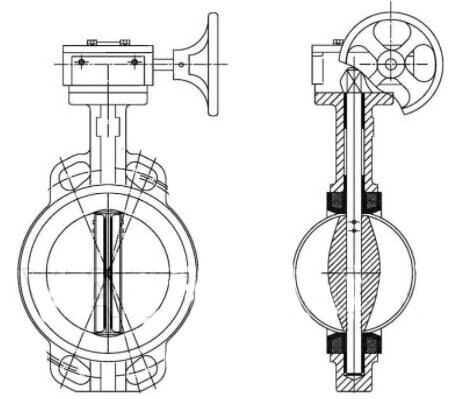

Structure and Characteristics of Concentric Butterfly Valves

Concentric butterfly valves, also known as centerline butterfly valves, are prevalent in various industries due to their unique design features and operational benefits. This article aims to delve into the structure and defining characteristics of concentric butterfly valves, emphasizing their advantages, particularly in reducing flow resistance.

The Structural Features

Concentric butterfly valves are well-known for their efficient fluid control capabilities, deriving from their unique structural features that ensure effectiveness and reliability. Here are the primary structural characteristics of concentric butterfly valves:

Characteristics and Advantages

Concentric butterfly valves offer distinct characteristics and advantages that make them preferred choices for fluid control applications. Below are the key characteristics and advantages of concentric butterfly valves:

Concentric butterfly valves, characterized by their centerline sealing structure and operational advantages, play a vital role in fluid control systems across various industries. Their capacity to reduce flow resistance underscores their significance, albeit within the constraints of specific operational environments.

The Structural Features

Concentric butterfly valves are well-known for their efficient fluid control capabilities, deriving from their unique structural features that ensure effectiveness and reliability. Here are the primary structural characteristics of concentric butterfly valves:

- Disc Configuration: The sealing centerline of the disc aligns precisely with the valve body's centerline and the rotational axis of the valve stem. Near the valve stem, the upper and lower ends of the disc are fashioned into smooth planes, ensuring close contact with the rubber seat liner to prevent leakage from both ends. Moreover, the outer edge of the disc is meticulously designed with a spherical profile, maintaining an appropriate surface roughness.

- Seat Design: Employing a soft sealing structure comprising rubber with a resin skeleton (fixed sleeve), the valve's seat liner is intricately crafted. Its inner ring, positioned higher than the valve body's cavity, is streamlined to reduce flow resistance effectively.

- Sealing Mechanism: During valve closure, the disc undergoes a rotation ranging from 0 to 90 degrees. This rotational movement gradually compresses the rubber seat liner, inducing elastic deformation and generating the necessary sealing pressure to ensure the valve's integrity.

Characteristics and Advantages

Concentric butterfly valves offer distinct characteristics and advantages that make them preferred choices for fluid control applications. Below are the key characteristics and advantages of concentric butterfly valves:

1. Flow Resistance Reduction: With a full-diameter channel design and a streamlined disc profile, coupled with the soft sealing structure of the seat liner, these valves optimize flow area, thereby minimizing flow resistance. This configuration enhances the valve's flow coefficient while concurrently reducing the fluid resistance coefficient.

2. Simplicity of Structure: Concentric butterfly valves boast a relatively straightforward design, facilitating ease of manufacturing and maintenance procedures.

3. Application Flexibility: These valves find suitability in low-pressure and ambient-temperature environments. However, they are not recommended for applications involving high temperatures or pressures.

2. Simplicity of Structure: Concentric butterfly valves boast a relatively straightforward design, facilitating ease of manufacturing and maintenance procedures.

3. Application Flexibility: These valves find suitability in low-pressure and ambient-temperature environments. However, they are not recommended for applications involving high temperatures or pressures.

Concentric butterfly valves, characterized by their centerline sealing structure and operational advantages, play a vital role in fluid control systems across various industries. Their capacity to reduce flow resistance underscores their significance, albeit within the constraints of specific operational environments.