Advantages and Applications of Bellows Sealed Globe Valves

As a crucial type of globe valve, the bellows sealed globe valve plays an irreplaceable role in industrial production. This article provides an in-depth analysis of the working principle, features, and applications of the bellows sealed globe valve to help readers better understand and utilize this critical equipment.

1. Working Principle

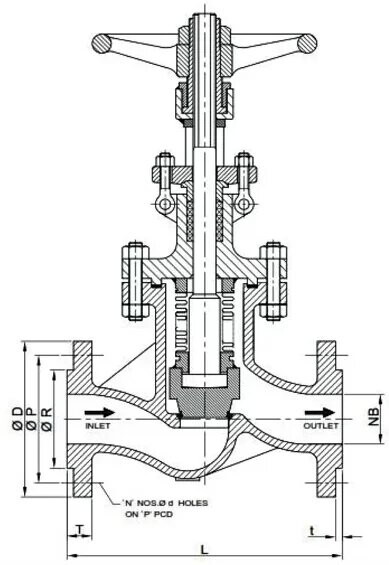

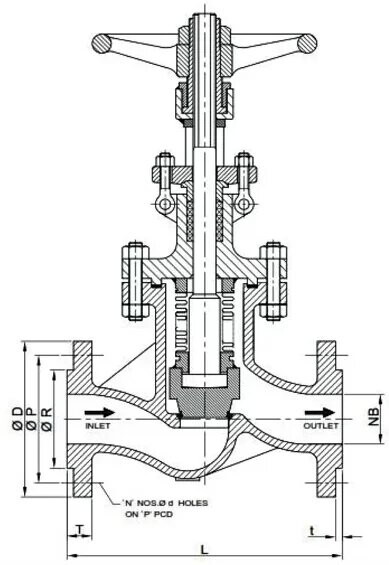

The bellows sealed globe valve operates by driving the valve head through the up and down movement of the stem. This action alters the distance between the valve disc and the valve seat, thereby controlling the valve's opening and closing. The operating component consists of a plug-shaped valve disc with sealing surfaces in either flat or conical form. The valve disc moves linearly along the fluid's central axis.

2. Features and Advantages

The bellows sealed globe valve offers several features and advantages that make it a preferred choice for various industrial applications:

3. Application Scenarios

Bellows sealed globe valves find widespread use in chemical production, primarily for controlling the flow of water, steam, compressed air, etc., in pipelines. However, they are unsuitable for highly viscous or crystallizing materials. Common application scenarios include:

In conclusion, bellows sealed globe valves, with their zero leakage design, durability, and excellent fluid control performance, are widely used across various industrial sectors. A deep understanding of their working principle and features enables better utilization of these valves, thereby improving production efficiency and ensuring smooth process operations.

1. Working Principle

The bellows sealed globe valve operates by driving the valve head through the up and down movement of the stem. This action alters the distance between the valve disc and the valve seat, thereby controlling the valve's opening and closing. The operating component consists of a plug-shaped valve disc with sealing surfaces in either flat or conical form. The valve disc moves linearly along the fluid's central axis.

2. Features and Advantages

The bellows sealed globe valve offers several features and advantages that make it a preferred choice for various industrial applications:

- Zero Leakage Design: Under high-temperature conditions, the stem does not come into contact with the medium, ensuring zero leakage.

- Durability: Possessing sufficient strength and toughness, the valve is capable of enduring thousands of cycles, providing a long service life.

- Ergonomic Design: The handwheel design conforms to ergonomics, facilitating simple, convenient, and comfortable operation.

- Fluid Control Performance: Effective regulation of flow and shut-off channels reduces the occurrence of water hammer.

- Compact Structure: Distinct appearance, easy operation, and simple maintenance characterize the valve's compact structure.

3. Application Scenarios

Bellows sealed globe valves find widespread use in chemical production, primarily for controlling the flow of water, steam, compressed air, etc., in pipelines. However, they are unsuitable for highly viscous or crystallizing materials. Common application scenarios include:

- Chemical Production: Used to control the flow of different media in chemical processes, ensuring process stability and safety.

- Oil and Gas Industry: Utilized for control and regulation in oil and gas pipeline systems, ensuring smooth and safe transportation.

- Water Supply and Heating Systems: Employed in urban water supply networks, heating systems, etc., to control water flow and heat transfer, maintaining the normal operation of these systems.

- Pharmaceutical and Food Industries: Regulating the flow of process media in pharmaceutical and food production, ensuring hygiene and safety during production.

In conclusion, bellows sealed globe valves, with their zero leakage design, durability, and excellent fluid control performance, are widely used across various industrial sectors. A deep understanding of their working principle and features enables better utilization of these valves, thereby improving production efficiency and ensuring smooth process operations.