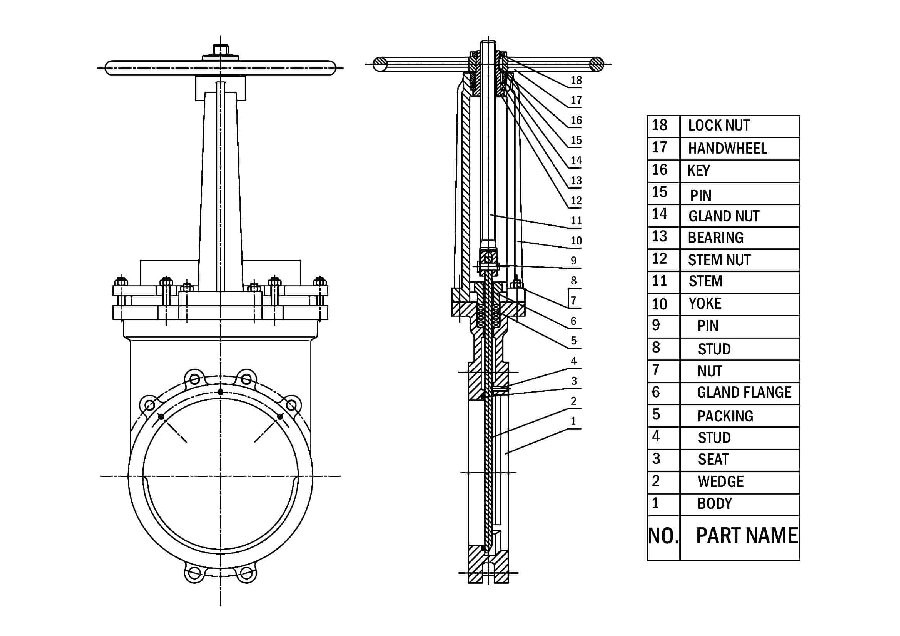

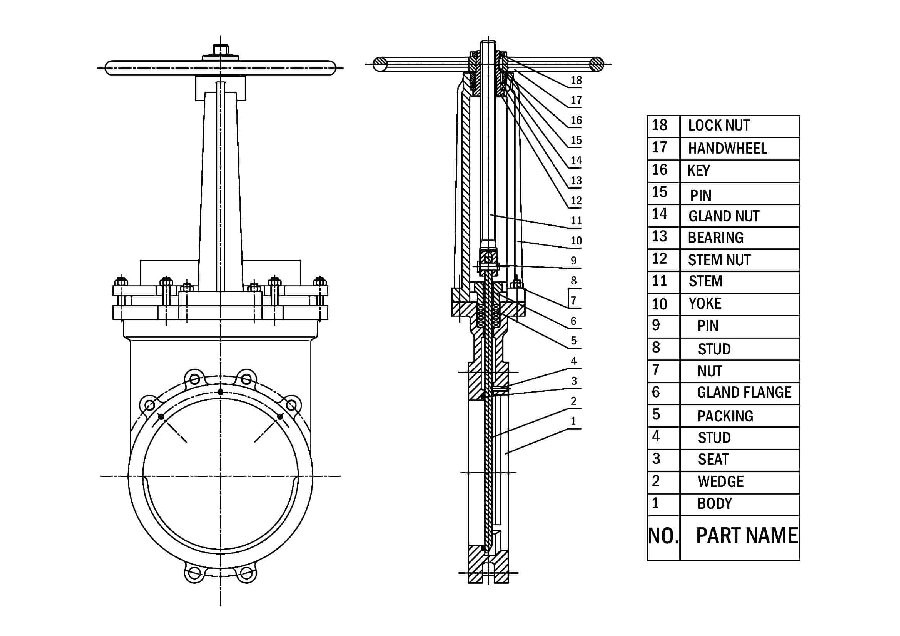

Discover Knife Gate Valves: Structure, Features and Applications

The knife gate valve, a specialized fluid control device, regulates flow using a blade-like gate that moves perpendicular to the fluid. Characterized by a versatile design with rigid and elastic gate options, this knife gate valve caters to specific application needs. This article explores the valve's structure, highlighting features like debris cleaning and corrosion resistance, and delves into its reliability across diverse applications, from coal washing pipelines to wastewater treatment.

About Its Structure and Sealing

The structure and sealing of a knife gate valve are crucial aspects that determine its functionality in controlling the flow of fluids. Here's an overview of the structure and sealing features of a typical knife gate valve:

Key Features of Knife Gate Valve

The key features of a knife gate valve encompass various aspects that define its design, functionality, and suitability for specific applications. Here are the key features of a knife gate valve:

The Versatile Applications

Knife gate valves find versatile applications across various industries due to their unique design and functionality. Here are some of the versatile applications of knife gate valves:

Knife gate valves, with their straightforward design, diverse sealing options, and flexible operation choices, emerge as an ideal solution across various industries. Their ability to automatically clean, resist corrosion, and adapt to high temperatures ensures reliability and efficiency in different operational conditions.

About Its Structure and Sealing

The structure and sealing of a knife gate valve are crucial aspects that determine its functionality in controlling the flow of fluids. Here's an overview of the structure and sealing features of a typical knife gate valve:

- Wedge and Elastic Gate: The wedge angle can change, and the gate can be rigid or designed to deform slightly for easier manufacturing and compensating for sealing face angle deviations.

- Bidirectional Sealing: O-ring seals on the valve seat enable sealing in both directions, ensuring better medium sealing.

- Self-Sealing and Forced Sealing: The valve can self-seal with medium pressure or use external force to press the gate against the seat, ensuring a sealed state.

Key Features of Knife Gate Valve

The key features of a knife gate valve encompass various aspects that define its design, functionality, and suitability for specific applications. Here are the key features of a knife gate valve:

- Automatic Debris Cleaning: The lifting gate sealing surface removes adhered substances, ensuring a clean seal.

- Corrosion-Resistant Design: Stainless steel gates prevent corrosion-related sealing leaks.

- Hard Metal Sealing Surface: Hard metal surfaces offer excellent wear resistance.

- Flexible Opening-Closing Structure: Short structure length, material savings, and support for pipeline strength are achieved through a scientifically designed upper-seal filling.

- Choice of Drive Mechanisms: Various driving modes can be chosen based on specific requirements.

- Adaptability to High Temperatures: Fluoroelastomer sealing surfaces improve the temperature range.

The Versatile Applications

Knife gate valves find versatile applications across various industries due to their unique design and functionality. Here are some of the versatile applications of knife gate valves:

- Mining and Steel Industry: Used in coal washing pipelines, slag slurry pipelines, and ash discharge pipelines.

- Purification Devices: Suitable for wastewater, slurry, mud, and clarified water containing suspended solids.

- Paper Industry: Applied to any concentration of pulp and water mixtures.

- Power Plant Ash Removal: Utilized in ash slurry fluid.

Knife gate valves, with their straightforward design, diverse sealing options, and flexible operation choices, emerge as an ideal solution across various industries. Their ability to automatically clean, resist corrosion, and adapt to high temperatures ensures reliability and efficiency in different operational conditions.