Understand Lift Plug Valves: Double Seal vs. Hard Sealing

On this page

Lift plug valves, as an essential type of industrial valve, are categorized into two types based on the material of their sealing surfaces: soft-sealing and hard-sealing. They play a crucial role in pipeline systems, controlling and regulating the flow of fluids through specific operating principles. This article will delve into the structure, working principles, and applications of these two types of lift plug valves across various industries.

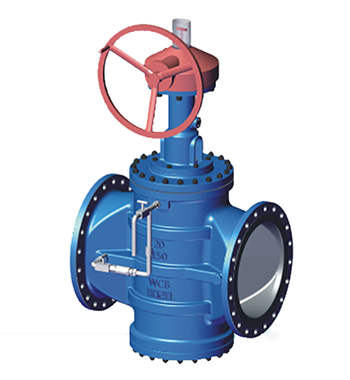

The double seal lift plug valve employs a soft sealing structure. The plug body is composed of three plates, forming a cylindrical plug with rubber sealing surfaces on both side plates, and a cylindrical wedge-shaped plug in the center.

Opening Process: When the valve is opened, the actuating mechanism lifts the plug, separating the side plates from the valve core and sealing surface combination. Then, the plug is rotated 90 degrees to fully open the valve.

Closing Process: To close the valve, the actuating mechanism rotates the combined plug 90 degrees to the closed position and pushes the plug downward. When the side plates contact the bottom of the valve body, the central wedge-shaped plug pushes the side plates inward through a ramp, causing the soft sealing surfaces to make contact with and compress against the valve body sealing surface.

The double seal lift plug valve features dual sealing and discharge functions, equipped with a pressure balancing device to prevent abnormal increases in system pressure and reduce instantaneous resistance during valve opening and closing. Due to the metal surface of the sealing ring making contact after compression, it also has a fire-resistant function. Maintenance is convenient, without the need to remove the valve body from the pipeline; simply remove and replace the side plates.

Widely used in industries such as petroleum, natural gas, metallurgy, mining, natural gas projects, light industry, textiles, marine terminals, food, and environmental water treatment, for the regulation and control of pipeline fluids.

The metal hard seal lift plug valve can seal the sealing surfaces on both sides of the valve seat without being limited by the medium flow rate. Its valve seat sealing surface is convex, making it easy to clean and less likely to accumulate crystalline media and solid particles, commonly used under high-temperature conditions in the chemical industry.

Handwheel Handle Lift Plug Valve: Compact structure, small size, and low fluid resistance. The working principle is to lift and fully open the plug and valve by raising the plug. When closing the valve, first rotate the handle to rotate the plug 90 degrees to the closed position, then rotate the handwheel to lower the plug and seal it.

Mechanical Cross Drive Lift Plug Valve: The working principle is to open by rotating the threads on the valve stem with the transmission device to lift the plug, separating the plug and valve body sealing surfaces, then rotate the plug 90 degrees to fully open the valve. When closing, rotate the mechanical cross to rotate the plug 90 degrees to the closed position, then lower it to make contact with and seal the valve body sealing surface.

The hard seal lift plug valve has a longer service life due to less scraping of the sealing surfaces during the opening and closing process.

Suitable for strict requirements in chemical plants, fluid control under high-temperature conditions, and unrestricted by medium flow rate.

In summary, lift plug valves play an irreplaceable role in various industries such as chemical, petroleum, natural gas, and food, through their unique design and operation. Whether it is the soft structure of the double seal or the heat-resistant characteristics of the hard seal, they can meet the needs of different process fluid control. With the advancement of industrial technology, the design of lift plug valves continues to be optimized, providing safer and more reliable valve solutions for various engineering projects.