Technical Features and Versatile Applications of Y Strainers

Y strainers, also referred to as strainers or filter valves, are vital components in pipeline systems responsible for conveying various media. They serve a critical role in filtering out mechanical impurities from liquids, thereby safeguarding equipment components and ensuring uninterrupted operations. In this article, we delve into the technical features, applications, and significance of Y strainers.

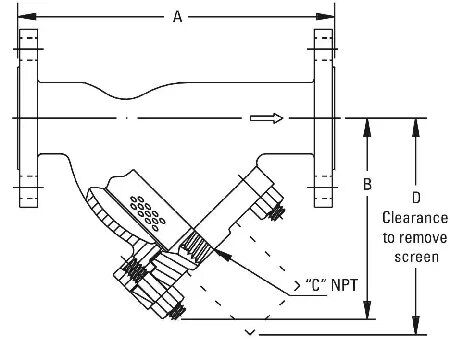

1. Principles of Operation

The operation of Y strainers is simple yet highly effective. When impurities exceed the filter pore size, they are intercepted and adhere to the filter screen, allowing clean fluid to pass through. Various testing methods, such as the bubble point method, diffusion flow method, and water intrusion method, ensure the efficacy of the filtration process.

2. Technical Features

Y strainers possess several technical features that underscore their importance in liquid treatment systems:

- High Filtration Precision: They ensure stable water quality output through high-precision filtration.

- Efficient Cleaning: Thorough cleaning allows for the lifelong use of filter screens without the need for replacements.

- Precision Operation: Sensitive control system responses facilitate adjustable operations based on different water sources and filtration precision requirements.

- Continuous, Reliable Operation: They ensure stability and reliability with continuous operation during backwashing, without interrupting normal water production.

- Energy Saving and Environmental Protection: Short backwashing durations and low backwash water consumption contribute to water and energy conservation efforts.

- Compact Design: Y strainers have a small footprint, offering flexibility, convenient installation, and ease of movement.

- Low Operating and Maintenance Costs: With few vulnerable parts, no consumables, and simple operation, Y strainers lead to low operating and maintenance costs.

- Automatic Backwashing: Equipped with self-searching and adaptive functions for automatic backwashing, they effectively address unstable water quality fluctuations.

3. Applications Across Industries

Y strainers find applications across diverse industries, including agricultural irrigation, water supply filtration systems, circulating water filtration, petrochemicals, electromechanical, and pharmaceutical wastewater ion exchange pretreatment. They are particularly crucial in treating domestic sewage and industrial wastewater, contributing to water resource recycling efforts.

In conclusion, Y strainers play a pivotal role in industrial production, environmental protection, and resource utilization. Their technical features make them indispensable components of liquid treatment systems, ensuring efficient filtration and contributing to the sustainability of water resources.