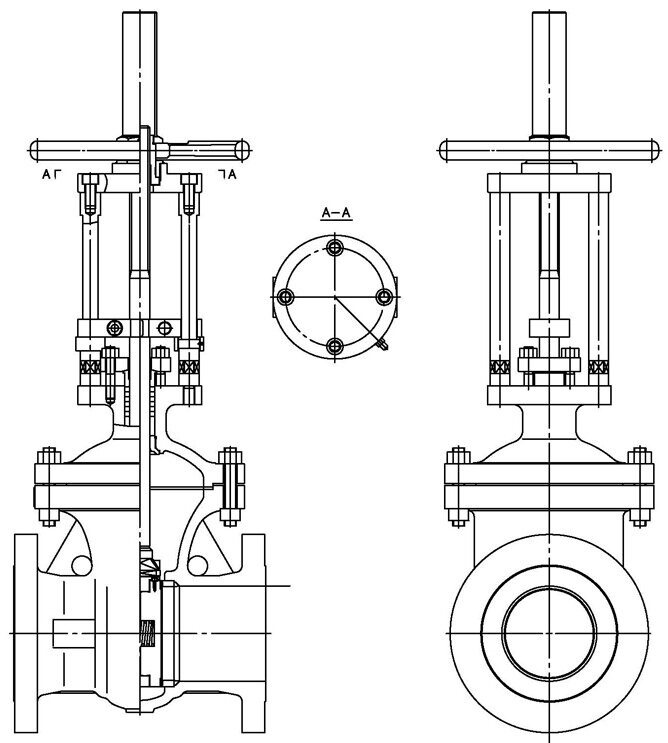

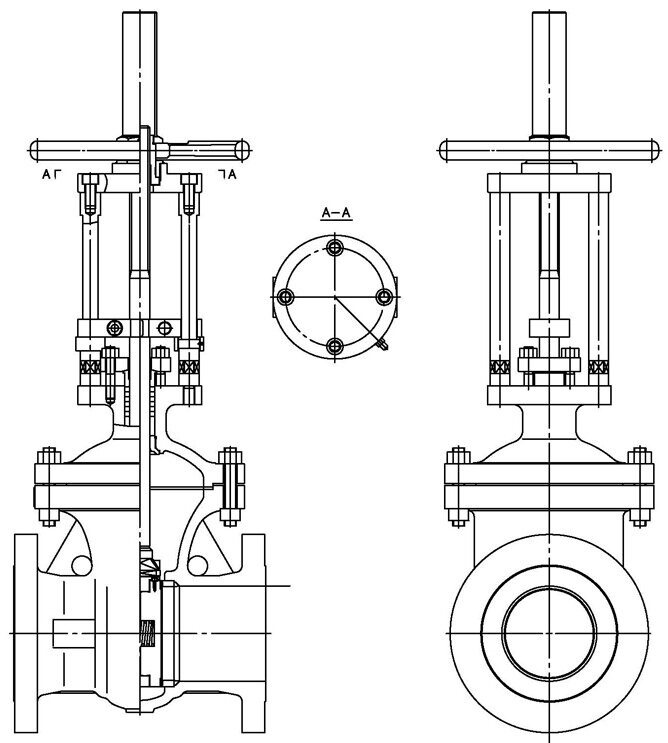

Parallel Double Disc Gate Valves: Advantages and Applications

The parallel double disc gate valve stands as a beacon of excellence across diverse industries, including water conservancy, chemical engineering, and urban water supply and drainage systems. Its sophisticated design not only ensures impeccable sealing but also guarantees dependable operation. In this discussion, we will meticulously examine the intricacies and wide-ranging applications of this remarkable gate valve.

1. Structural Characteristics and Advantages

The structural prowess of the parallel double disc gate valve manifests in its ability to minimize turbulence and fluid resistance, thereby reducing energy consumption. It offers versatility in operation, accommodating manual, electric, or pneumatic switching methods. During operation, it exhibits swift flow shut-off and adjustment, ensuring system stability and reliability.

2. Application Scenarios

The parallel double disc gate valve finds extensive use in water conservancy engineering, chemical processes, and urban water supply and drainage systems.

As a robust valve renowned for its exceptional performance and broad applicability, the parallel double disc gate valve has become indispensable across various sectors. With ongoing technological advancements and increasing application demands, it will continue to evolve and optimize, delivering greater convenience and benefits to human endeavors and daily life.

1. Structural Characteristics and Advantages

The structural prowess of the parallel double disc gate valve manifests in its ability to minimize turbulence and fluid resistance, thereby reducing energy consumption. It offers versatility in operation, accommodating manual, electric, or pneumatic switching methods. During operation, it exhibits swift flow shut-off and adjustment, ensuring system stability and reliability.

Efficient Lubrication Mechanism: A stem nut with an internally designed structure facilitates effortless lubricant injection for smooth operation.

Enhanced Sealing Assurance: Packing equipped with spacers allows easy sealing grease injection, ensuring stem sealing and lubrication reliability.

Safety Priority: The valve's inlet side is designed as a pressure relief type under high temperature and pressure conditions, prioritizing safety.

Optimized Flow Dynamics: In the fully open position, the straight passage minimizes flow resistance and pressure loss, aiding pipeline cleaning.

All-Weather Durability: Its fully enclosed design ensures excellent protection and usability in all weather conditions.

Prevention of Stem Jamming: The two-part packing gland design prevents stem jamming issues.

Reliable Sealing Structure: A metal corrugated gasket in the middle flange ensures reliable sealing.

Thermal Expansion Prevention: Separate sealing mechanism parts ensure sealing integrity even under temperature-induced deformations, preventing gate jamming due to thermal expansion.

Innovative Design Approach: The sealing structure, featuring two balanced gates and wedge tightening devices, replaces the conventional wedge gate valve structure.

Enhanced Sealing Assurance: Packing equipped with spacers allows easy sealing grease injection, ensuring stem sealing and lubrication reliability.

Safety Priority: The valve's inlet side is designed as a pressure relief type under high temperature and pressure conditions, prioritizing safety.

Optimized Flow Dynamics: In the fully open position, the straight passage minimizes flow resistance and pressure loss, aiding pipeline cleaning.

All-Weather Durability: Its fully enclosed design ensures excellent protection and usability in all weather conditions.

Prevention of Stem Jamming: The two-part packing gland design prevents stem jamming issues.

Reliable Sealing Structure: A metal corrugated gasket in the middle flange ensures reliable sealing.

Thermal Expansion Prevention: Separate sealing mechanism parts ensure sealing integrity even under temperature-induced deformations, preventing gate jamming due to thermal expansion.

Innovative Design Approach: The sealing structure, featuring two balanced gates and wedge tightening devices, replaces the conventional wedge gate valve structure.

2. Application Scenarios

The parallel double disc gate valve finds extensive use in water conservancy engineering, chemical processes, and urban water supply and drainage systems.

Water Conservancy Engineering: It regulates water flow size and direction, optimizing water resource allocation.

Chemical Processes: It controls material flow rate and pressure, ensuring reaction stability and safety.

Urban Water Systems: It manages water flow and pressure, guaranteeing system stability and reliability.

Chemical Processes: It controls material flow rate and pressure, ensuring reaction stability and safety.

Urban Water Systems: It manages water flow and pressure, guaranteeing system stability and reliability.

As a robust valve renowned for its exceptional performance and broad applicability, the parallel double disc gate valve has become indispensable across various sectors. With ongoing technological advancements and increasing application demands, it will continue to evolve and optimize, delivering greater convenience and benefits to human endeavors and daily life.