High-Temperature Hard Seal Ball Valve: Characteristics and Maintenance

In industrial fluid control, the high-temperature hard seal ball valve is indispensable. Engineered for durability in harsh conditions, these ball valves play a crucial role in regulating fluid flow across various industries. This article provides an overview of their structure, characteristics, and the essential maintenance required for optimal performance.

About High-temperature Hard Seal Ball Valve

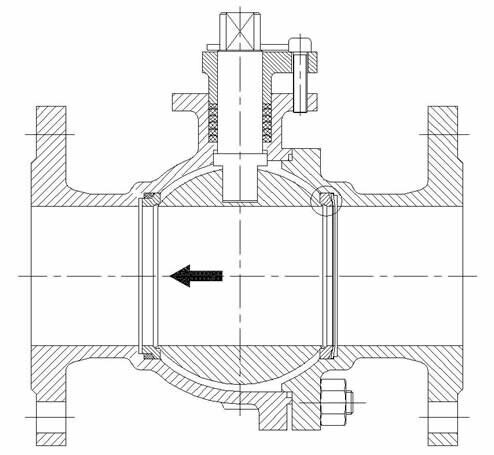

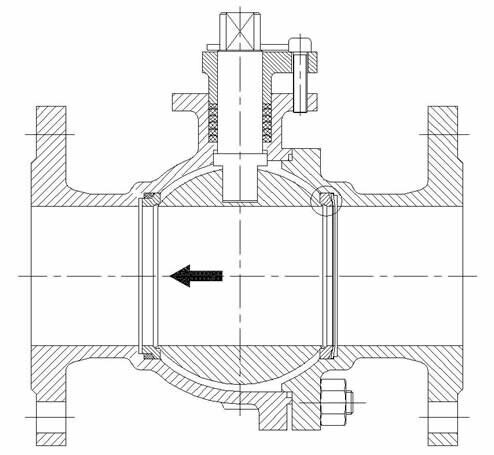

The high-temperature hard seal ball valve is a commonly used fluid control device in industrial production. Its design aims to adapt to various corrosive media pipelines and equipment. Structurally similar to other similar valves, it mainly consists of valve body, valve stem, and actuator. Among them, the key components of the ball valve are the ball and the seat. The ball rotates under the action of the valve actuator, playing a role in cutting off or regulating the flow of fluid, while the seat supports the ball and ensures good sealing performance on the seat ring.

The Major Characteristics

The high-temperature hard seal ball valve boasts several key characteristics essential for its performance and reliability in industrial applications:

Maintenance Methods for the Ball Valve

To ensure the long-term stable operation of the high-temperature hard seal ball valve, regular maintenance is required. Common methods include:

In summary, the high-temperature hard seal ball valve plays a critical role in industrial fluid control, offering durability and effectiveness in harsh environments. Through careful design and maintenance, these valves ensure reliable operation, contributing to the efficiency and longevity of industrial processes.

About High-temperature Hard Seal Ball Valve

The high-temperature hard seal ball valve is a commonly used fluid control device in industrial production. Its design aims to adapt to various corrosive media pipelines and equipment. Structurally similar to other similar valves, it mainly consists of valve body, valve stem, and actuator. Among them, the key components of the ball valve are the ball and the seat. The ball rotates under the action of the valve actuator, playing a role in cutting off or regulating the flow of fluid, while the seat supports the ball and ensures good sealing performance on the seat ring.

The Major Characteristics

The high-temperature hard seal ball valve boasts several key characteristics essential for its performance and reliability in industrial applications:

1. Material Selection: Specifically using hard alloy materials to improve wear resistance, corrosion resistance, and longer service life. High molecular materials are used on the seat to ensure pressure resistance and sealing level.

2. High-Temperature Resistance: It has a very high operating temperature, and its high-temperature operation standards and specifications are unique. The temperature resistance depends on the choice of hard alloy materials.

3. Multiple Operating Modes: The actuator is flexible and diverse, electric ball valves can achieve remote control operation, and have multiple working modes such as manual and automatic integration.

2. High-Temperature Resistance: It has a very high operating temperature, and its high-temperature operation standards and specifications are unique. The temperature resistance depends on the choice of hard alloy materials.

3. Multiple Operating Modes: The actuator is flexible and diverse, electric ball valves can achieve remote control operation, and have multiple working modes such as manual and automatic integration.

Maintenance Methods for the Ball Valve

To ensure the long-term stable operation of the high-temperature hard seal ball valve, regular maintenance is required. Common methods include:

- Close the Valve and Disassemble for Inspection: First, close the valve and disassemble the entire valve for inspection and maintenance.

- Cleaning the Valve: Prepare a mixture for cleaning, disassemble all parts, and clean them using detergents, steel wires, oil cotton, and cleaning agents.

- Inspect Valve Components: Pay special attention to sealing parts, and repair or replace them promptly if damage is found.

- Lubrication: Apply rust-proof oil or lubricating oil in moderation, being careful not to apply too much. For valves with torque handwheels, they can be removed and greased.

- Overall Inspection: Ensure that all parts are correctly installed and operating properly.

- Correct Installation: Use professional tools and equipment for correct installation to avoid excessive weight or wear.

- Record Usage: Maintain a log of valve usage, promptly identify and solve problems to improve product quality.

- By following these maintenance methods, the service life of high-temperature hard seal ball valves can be effectively extended, and their performance can be ensured to remain stable.

In summary, the high-temperature hard seal ball valve plays a critical role in industrial fluid control, offering durability and effectiveness in harsh environments. Through careful design and maintenance, these valves ensure reliable operation, contributing to the efficiency and longevity of industrial processes.