Exploring Three-Piece Ball Valves: Features and Installation

Three-piece ball valves are widely esteemed among the various types of valves due to their simple yet effective structure and convenient installation and maintenance. This article aims to provide a detailed overview of the structure, advantages, and installation essentials of three-piece ball valves, enhancing readers' understanding and application of this crucial fluid control equipment.

About Three-piece Ball Valve

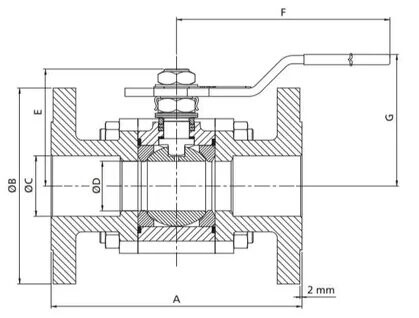

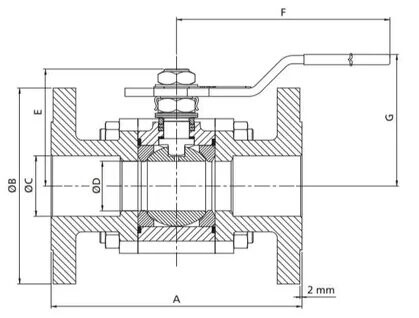

Three-piece ball valves typically consist of left and right auxiliary valve bodies with a central main valve body, connected via bolts for easy installation and disassembly. They can be connected using methods such as flange connection, threaded connection, welding, clamp connection, and sleeve connection. Materials commonly used include WCB cast steel, 304 stainless steel, and 316 stainless steel, chosen to adapt to diverse working environments and media requirements.

The Major Advantages

Three-piece ball valves offer several significant advantages, making them popular choices in various industries. Here are the major advantages of three-piece ball valves:

Installation Essentials

The installation of three-piece ball valves involves several essential steps to ensure proper functioning and long-term reliability. When installing three-piece ball valves, several key considerations should be observed:

In summary, three-piece ball valves play an indispensable role in industrial fluid control systems due to their superior characteristics and convenient installation and maintenance. When selecting and applying these valves, it's essential to consider their advantages and suitability for specific scenarios to ensure stable and efficient system operation.

About Three-piece Ball Valve

Three-piece ball valves typically consist of left and right auxiliary valve bodies with a central main valve body, connected via bolts for easy installation and disassembly. They can be connected using methods such as flange connection, threaded connection, welding, clamp connection, and sleeve connection. Materials commonly used include WCB cast steel, 304 stainless steel, and 316 stainless steel, chosen to adapt to diverse working environments and media requirements.

The Major Advantages

Three-piece ball valves offer several significant advantages, making them popular choices in various industries. Here are the major advantages of three-piece ball valves:

Low Fluid Resistance: With larger flow passage dimensions, they exhibit strong flow capacity and minimal fluid resistance, enabling efficient fluid control within pipeline systems.

Simple and Lightweight Structure: Their straightforward design, compact size, and light weight facilitate easy installation and operation, suitable for applications with stringent space constraints.

Reliable Sealing: Utilizing sealing materials such as plastics, they offer excellent sealing performance, ensuring reliability across various media and vacuum systems.

Convenient Operation: These valves open and close rapidly with a 90° rotation, making them suitable for remote control applications.

Easy Maintenance: Featuring a simple structure and movable sealing rings, they facilitate convenient disassembly and replacement, reducing maintenance costs and downtime.

Effective Media Isolation: When fully open or closed, the sealing surfaces of the ball and seat isolate from the media, preventing erosion of the valve sealing surface by the media.

Wide Applicability: With sizes ranging from a few millimeters to several meters, they can be applied across a broad spectrum of operating conditions, from high vacuum to high pressure.

Simple and Lightweight Structure: Their straightforward design, compact size, and light weight facilitate easy installation and operation, suitable for applications with stringent space constraints.

Reliable Sealing: Utilizing sealing materials such as plastics, they offer excellent sealing performance, ensuring reliability across various media and vacuum systems.

Convenient Operation: These valves open and close rapidly with a 90° rotation, making them suitable for remote control applications.

Easy Maintenance: Featuring a simple structure and movable sealing rings, they facilitate convenient disassembly and replacement, reducing maintenance costs and downtime.

Effective Media Isolation: When fully open or closed, the sealing surfaces of the ball and seat isolate from the media, preventing erosion of the valve sealing surface by the media.

Wide Applicability: With sizes ranging from a few millimeters to several meters, they can be applied across a broad spectrum of operating conditions, from high vacuum to high pressure.

Installation Essentials

The installation of three-piece ball valves involves several essential steps to ensure proper functioning and long-term reliability. When installing three-piece ball valves, several key considerations should be observed:

1. Thorough Cleaning: Flush and clean the valve and pipeline thoroughly while fully open to ensure internal cleanliness.

2. Comprehensive Testing: Conduct comprehensive testing before installation to ensure the valve's performance is unaffected by factors such as vibration.

3. Pipeline Cleaning: Clean and remove any impurities remaining in the pipeline before connection to prevent damage to the valve seat and ball.

4. Avoid Suspension: Refrain from using the valve's actuator as a lifting point during installation to prevent damage to the actuator and accessories.

5. Correct Orientation: Install the valve horizontally or vertically as required to ensure proper operation.

6. Pipeline Support: Ensure the pipeline near the installation point is free from sagging or external forces by using pipeline supports or braces to eliminate deviations.

7. Torque Locking: After connecting the valve to the pipeline, use the specified torque cross-locking method to tighten the flange connection bolts securely.

2. Comprehensive Testing: Conduct comprehensive testing before installation to ensure the valve's performance is unaffected by factors such as vibration.

3. Pipeline Cleaning: Clean and remove any impurities remaining in the pipeline before connection to prevent damage to the valve seat and ball.

4. Avoid Suspension: Refrain from using the valve's actuator as a lifting point during installation to prevent damage to the actuator and accessories.

5. Correct Orientation: Install the valve horizontally or vertically as required to ensure proper operation.

6. Pipeline Support: Ensure the pipeline near the installation point is free from sagging or external forces by using pipeline supports or braces to eliminate deviations.

7. Torque Locking: After connecting the valve to the pipeline, use the specified torque cross-locking method to tighten the flange connection bolts securely.

In summary, three-piece ball valves play an indispensable role in industrial fluid control systems due to their superior characteristics and convenient installation and maintenance. When selecting and applying these valves, it's essential to consider their advantages and suitability for specific scenarios to ensure stable and efficient system operation.