Eccentric Plug Valves: Design and Applications

On this page

In modern industry, eccentric plug valves have become crucial fluid control devices due to their unique design and superior performance. Their structural characteristics enable them to excel in handling high-pressure, corrosive media, and wastewater treatment environments. This article provides a systematic overview of the structural design, sealing and seat systems, operational performance, and real-world applications of eccentric plug valves. Through detailed analysis, we aim to offer a comprehensive understanding of the advantages and applicability of eccentric plug valves across various industrial settings.

The structural design of eccentric plug valves features innovative and optimized elements. Understanding this design is essential to grasp the valve's functions and benefits. We will delve into key design elements such as axis offset, plug design, and seat structure, all of which significantly impact the valve's operational performance and reliability.

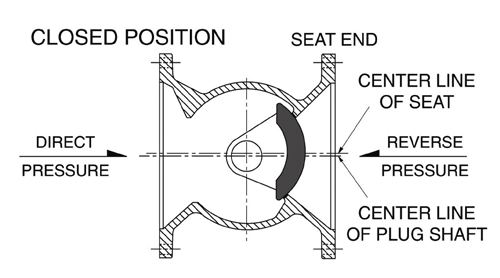

One of the distinctive features of the eccentric plug valve is its axis offset. Unlike traditional ball valves, where the axis is perfectly aligned, the eccentric plug valve has an axis that is slightly offset from the seat. This design ensures that the plug always stays away from any supporting surfaces before closing, reducing wear and enhancing sealing performance. Similar to the eccentric cam design of high-function butterfly valves, this offset is particularly suited for high-pressure or high-temperature applications. The eccentric structure ensures that the plug can automatically position itself in a fail-closed scenario, reducing reliance on actuator failure springs and enhancing system reliability and safety.

The plug design of the eccentric plug valve exhibits notable features. Its shape resembles that of a gate valve plug, with the plug head mounted perpendicular to the shaft. Compared to spherical designs, this design allows for more precise flow control and efficient sealing performance. The plug's design is akin to an improved quick-opening plug, enabling it to tightly seal against the seat when closed, providing excellent sealing efficiency.

The performance of the seat and sealing system in eccentric plug valves directly impacts the overall valve performance. Optimizing the seat structure and sealing performance is crucial for ensuring the valve's reliability and durability in various working environments. This section will analyze the seat structure, sealing performance, and their effectiveness in real-world applications.

The seat structure in eccentric plug valves is designed to enhance sealing performance. The seat typically features a floating seat support frame with screw fixation and automatic centering. This design helps to maintain the correct position of the seat during operation, ensuring better sealing performance. Depending on the working environment, seat materials can be metal or soft elastomers, optimized based on the nature of the media and operational conditions.

The eccentric sealing design of the plug valve uses the principle of eccentric motion to gradually tighten the contact between the plug and seat when closing, achieving effective sealing. When opening, the plug quickly separates from the seat, reducing contact wear and making operation more effortless. This design significantly lowers operating torque and extends the valve's service life. It is particularly well-suited for environments requiring frequent operation or handling corrosive media.

The operational performance and fluid control capabilities of eccentric plug valves are key reasons for their popularity in various industrial applications. Through optimized flow path design and material selection, these valves provide efficient flow regulation and low head loss. This section explores how these design optimizations enhance the valve's operational efficiency and adaptability.

The rectangular through-flow path design of the eccentric plug valve helps reduce head loss and optimize flow control linearity. The design not only increases fluid velocity but also minimizes the deposition of impurities caused by fluid flow. This makes eccentric plug valves perform exceptionally well in urban sewage, industrial wastewater, slurry, and clean water environments, suitable for isolation or regulation devices.

The valve's ductile iron plug framework is covered with high-performance rubber, ensuring excellent sealing elasticity and preventing rubber peeling and erosion. Seat materials can include pure nickel, stainless steel, or other specialty materials, combined with new surface treatment technologies to enhance the valve's corrosion and wear resistance. This material selection is particularly important for handling corrosive or high-solid-content media.

Structural optimizations in eccentric plug valves allow them to perform well in demanding environments. As technology advances, lightweight designs and corrosion protection measures further extend their application range. This section will analyze how these structural optimizations enhance valve performance and explore their real-world applications and advantages.

The high-strength ductile iron valve body design of eccentric plug valves reduces weight by over 20% compared to traditional plug valves. Structural optimizations not only shorten the fluid residence time in the flow path but also increase fluid velocity and reduce impurity deposition. Additionally, the valve's compact body spacing and self-flushing functionality make it suitable for handling wastewater or fluids with solid impurities.

The design of eccentric plug valves enables them to excel in various harsh working environments. The valve's interior and exterior surfaces are coated with non-toxic epoxy resin to prevent rusting, making them suitable for wastewater systems and harsh outdoor or underground environments. The rectangular flow path design provides good linear performance in flow regulation, ideal for applications requiring precise control of flow and pressure.

Eccentric plug valves, with their unique structural design, superior sealing performance, and efficient fluid control capabilities, demonstrate strong adaptability and performance across multiple fields. Their optimized design makes them an ideal choice for applications in urban sewage, industrial wastewater, slurry, and clean water environments. A thorough understanding of eccentric plug valves enhances their application across diverse industrial and environmental conditions, improving overall system performance and reliability.