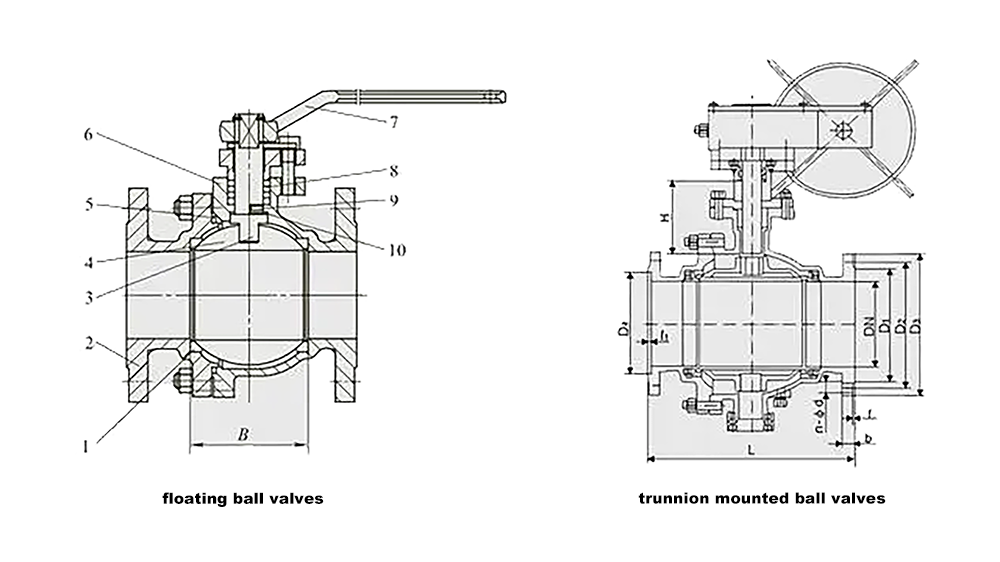

Floating Ball Valve: The ball in a floating ball valve is movable, and under the pressure of the medium, it can generate a certain displacement and press tightly against the sealing surface at the outlet to ensure sealing. This ball valve has a small volume, light weight, simple structure, and excellent sealing performance. However, the ball transfers all the loads from the working medium to the outlet sealing ring, so it is essential to consider whether the sealing ring material can withstand the working load of the ball medium.

Trunnion Mounted Ball Valve: The ball in a fixed ball valve is stationary and does not move when pressurized. Trunnion mounted ball valves come with a floating valve seat. Under the pressure of the medium, the ball valve seat moves, pressing the sealing ring tightly against the ball to ensure sealing. Typically, bearings are installed on the upper and lower axes of the ball to reduce operating torque, making trunnion mounted ball valves suitable for high pressure and large diameter valves. In recent years, oil-sealed ball valves have emerged to enhance sealing reliability by injecting specially formulated lubricating oil between the sealing surfaces, reducing operating torque and making them more suitable for high-pressure, large-diameter ball valves.

Features and Performance:

-

Floating Ball Valve Features and Performance:

- Small volume, light weight, and simple structure.

- The ball has a free-floating function, ensuring good sealing.

- Quick switch and compact structure.

- Low torque operation with a 90-degree rotation to close the valve.

- The ball's channel diameter matches the pipe diameter, providing low flow resistance and high flow capacity.

- Down-mounted stem design ensures safety by preventing stem ejection accidents.

-

Trunnion Mounted Ball Valve Features and Performance:

- Suitable for various high-pressure pipelines.

- Applicable to a wide range of media, including water, steam, oil, liquefied gas, natural gas, acids, and more.

- Commonly driven by worm gear, manual, electric, and pneumatic methods.

- Mostly flange-connected, but also available in welded forms.

- The use of bearings on the upper and lower axes reduces operating torque.

- Oil-sealed ball valves enhance sealing and are well-suited for high-pressure, large-diameter applications.

Differences between Floating and Trunnion Mounted Ball Valves:

-

Sealing Structure:

- In a floating ball valve, the ball core can move along the flow channel, while the valve seat remains stationary.

- In a trunnion mounted ball valve, the ball core cannot move along the flow channel, and the valve seat can move.

-

Application Conditions:

- Floating ball valves are more suitable for low pressure and small diameter applications.

- Trunnion mounted ball valves are commonly used in high-pressure and large-diameter scenarios, such as in natural gas pipelines with pressures reaching Class 1500 LB and diameters of DN1500.

-

Seat Sealing:

- Trunnion mounted ball valves can achieve various seat sealing functions, including front and rear unidirectional sealing, front and rear bidirectional sealing, and center cavity relief.

- Floating ball valves rely on the outlet valve seat for forced sealing.

In summary, both floating and trunnion mounted ball valves have their unique advantages and are suitable for different operating conditions based on factors such as pressure, diameter, and sealing requirements.