Fully Welded Ball Valve, DIN EN 10217-2 ST 37.8, DN40, PN25

Key Specifications / Features

Model No.: JSC-240131-FWBV-01

Hits: 101

We are pleased to offer fully welded floating ball valves designed for District Heating applications. Crafted from high-quality Carbon Steel, our valves meet DIN EN 10217-2 ST 37.8 standards, ensuring robustness and reliability. With a size of 1-1/2 inches (DN40) and pressure ratings of 300 LB and PN25, our valves are engineered to meet your specific needs. Featuring a reduced bore and butt weld (BW) end connections, they provide efficient fluid control and easy installation.

Request a quote

Tags

Detail Information

Fully Welded District Heating Ball Valve

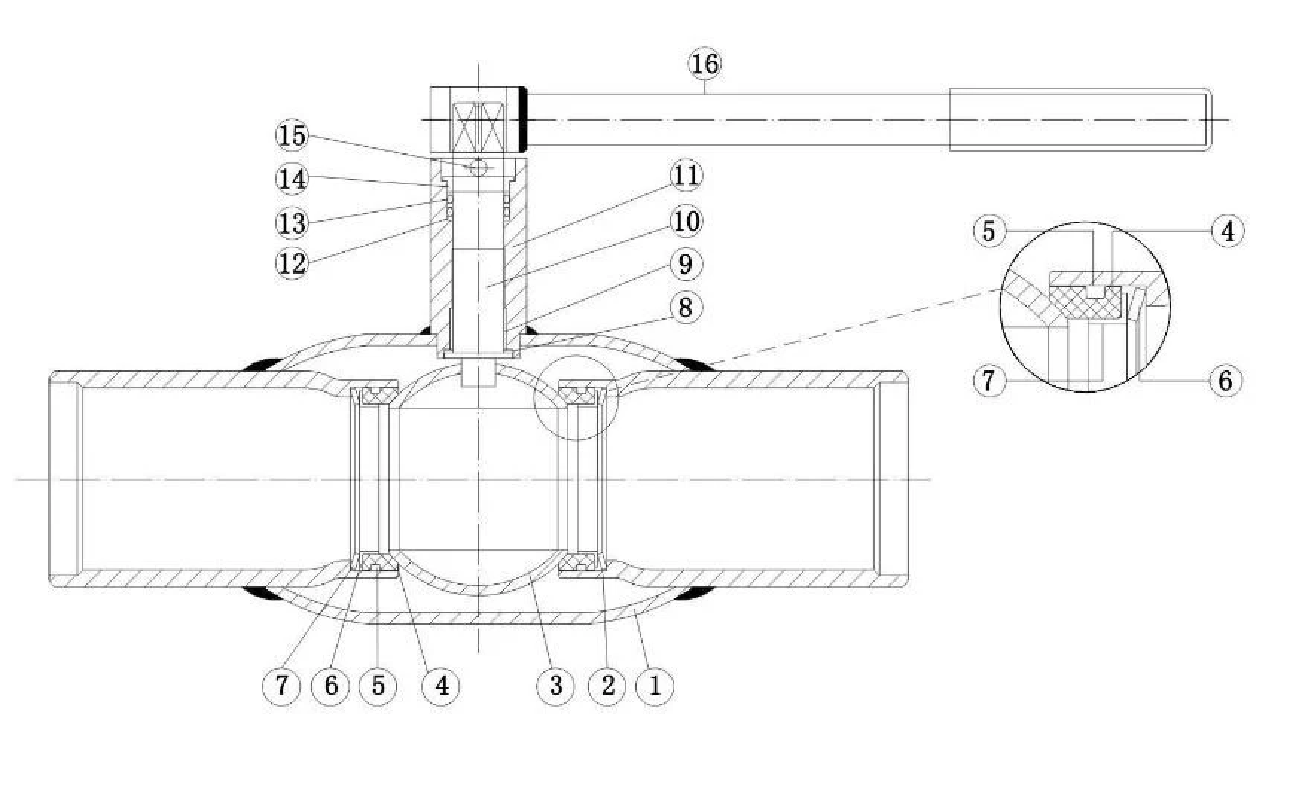

Valve Description: Ball valve, floating type, fully welded, soft seat, reduced bore

Body material: ST 37.8 (Carbon Steel)

Ball material: SS 304

Nominal diameter: DN40 (1-1/2 Inch)

Nominal class: PN25 (Class 300 LB)

End connection: BW

Seat: PTFE + C

Face to face: MFR

Mode of operation: Lever

Design: DIN EN 10217-2, API 6D

Test and inspection: API 598

With Q61F fully welded Ball Valves, there will be no external leakage. Processing of the ball valve has advanced computer detector tracking test, so the ball machining precision is high.

As the valve material is same as pipe material, there will be no stress uneven or deformation when earthquake or vibration caused by the vehicle passing through. Ball valve seal ring adopts RPTFE with 25% carbon to ensure completely no leakage.

Full weld ball valve can be buried directly underground, full weld ball valve do not need to build large valve wells, simply set up small shallow wells on the ground, greatly saving construction costs and engineering time. According to the pipeline construction and design requirements, ball valve body length and stem height can be adjusted.

Product Characteristics

1. The overall body structure welding, there will be no external leakage.

2. The valve seat composed by a PTFE sealing ring and springs which has a strong adapt ability to changes of pressure and temperature, within the using range there will be no any leaks.

3. Stem leakage prevention structure, the bottom of the stem has a PTFE seal the puncture, there are two O-rings above, composed of two PTFE gaskets ensure no leakage.

4. The same body material and pipe material, stress will not appear uneven, it will not because of the earthquake and the vehicle passes through the ground sometimes cause extrusion.

5. The body is light and easy to keep temperature not down.

6. We can adjust the body length and stem height according to construction and design requirements of the pipeline.

7. The ball's machining precision is very high easy to operation, no adverse interference.

8. Can use welded and flanged two kinds connection type.

Comment Form