EN 593 Wafer Butterfly Valve, ASTM A216 WCB, DN800, PN16

Key Specifications / Features

Model No.: JSC-240111-EBV-04

Hits: 88

Our EN 593 Butterfly Valve, crafted from robust Carbon Steel ASTM A216 WCB, adheres to high-quality standards. With an impressive size of DN800 (32 inches) and a reliable pressure rating of PN16 (Class 150 LB), this valve is ideal for various industrial applications. The metal-to-metal seat ensures durability and resilience in demanding conditions. The triple eccentric design enhances precision and efficiency in controlling fluid flow. Its wafer end configuration offers easy and versatile installation.

Request a quote

Tags

Detail Information

Metal to Metal Seat Butterfly Valve

Valve Description: Butterfly valve, triple eccentric, full metal seat, uni-directional, bi-directional, cast carbon steel

Body material: ASTM A216 WCB

Disc material: ASTM A351 CF8

Nominal diameter: DN800, 32 Inch

Nominal class: PN16, Class 150 LB

Design / Manufacture: EN 593

Face to face: ISO 5752

Test and inspection: EN 12266

End connection: WAFER

Metal seat: Full Metal SS 304

Mode of operation: Gear

Three eccentric laminate hard seal flange butterfly valve is a long-life, energy-saving butterfly valve. Its structure adopts the three-dimensional core principle design, and the valve seat adopts the laminate stainless steel with graphite structure of hard and soft sealing compatibility, with exquisite processing and advanced technology. This product is composed of valve body, butterfly disc, laminate seal as valve seat, valve stem, transmission mechanism and other main components. It is widely used in metallurgy, electric power, petroleum, chemical industry, air, gas, combustible gas and water supply and drainage pipeline.

Metal to Metal Seat Butterfly Valve-Features

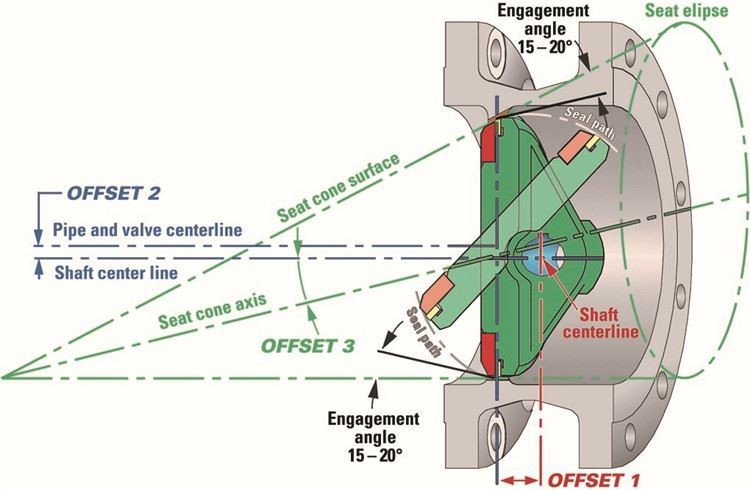

There are three eccentrics (offsets): the first eccentric, the shaft deviated from the centerline of sealing face; The second eccentric, the shaft deviated from the centerline of pipe and valve; The third eccentric the distinctive included angle between oblique taper angle of eccentric seat and centerline of pipe, thus making seat completely disengaged from the sealing ring during the whole process of open and close. This structure not only uses cam effect, but also eliminates the possibility of abrasion and leakage.

1. Elastic property of composite metal sealing ring to perform zero leakage.

2. Torque seal to ensure two-way zero leakage.

3. STL one piece hard surface seat may be adapted to many working conditions, which is featured by long service life and easy maintenance.

4. One piece cast body, face to face dimensions conforming to ISO 5752, ASME B16.10 and API 609, replacement to high performance butterfly valves and other types of valves, easy and flexible installation.

5. Intrinsically fireproof property thanks to all metal structure and leak tight performance.

6. Anti-blowout stem for high dependability, completely conforming to API 609

7. The stem of triple eccentric butterfly valve is a shaft, and the stem and disc are connected by key or pin-key combination.

Metal to Metal Seat Butterfly Valve-Specifications and Materials

1. Design: API 609, ASME B16.34, AWWA C504, BS EN 593

2. Face to Face: API 609, AWWA C504, BS 2080, and ISO 5752

3. Flange End: ASME B 16.5, ASME B16.47, BS EN 1092, ISO 7005, GOST

4. Inspection Test: API 598, BS EN 12266, ISO 528

5. Materials Choose Body Materials: Carbon Steel ASTM A216 WCB, WCC, Low Temperature Carbon Steel ASTM A352 LCB, A352 LCC, A352 LC1, A352 LC2; Alloy Steel Chrome Moly ASTM A217 WC6, A217 C5, A217 WC5, A217 C12, A217 C12A, A217 WC9, 1.7335, 1.7380, 1.7362, 1.7386, 1.4903; STAINLESS STEEL ASTM A351 CF3, A351 CF8, A351 CF3M, A351 CF8M, A351 CF8C, 1.4301, 1.4306, 1.4401, 1.4404, 1.4550, 1.4438; ALLOY 20 ASTM A351 CN7M, N08020, 1.4438; DUPLEX STEEL 2205 ASTM A351 CD3MN, A890 2205, S31803, 1.4462; SUPER DUPLEX STAINLESS STEEL ASTM A351 CD4MCu, A890 5A, S32750, 1.4501; SUPER DUPLEX F55, ASTM A995 CD3MWCuN, S32760

6. Disc Materials: ASTM A216 WCB, WCC, ASTM A352 LCB, ASTM A351 CF8M, CF3M, CF8, CF3, ASTM A890 4A, 5A, ALLOY 20, Duplex Stainless Steel, Monel, Hastelloy Steel

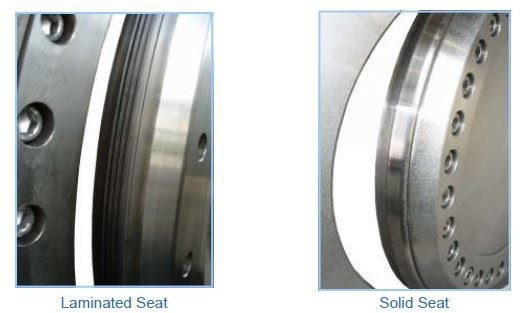

7. Seat Materials: Metal to Metal seat, Solid Seat

8. Pressure Range: PN10, PN16, PN25, PN40, PN63, PN100, 150 LB, 300 LB, 600 LB, 900 LB (PN10-PN100, Class 150-900 LB)

9. Size Range: DN50-DN3200, 2 Inch - 128 Inch

10. Drive Mode: Manual/Worm gear/Electric/Pneumatic

11. Field of Application: Electric /Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

Comment Form